What are the advantages of using cup filling machines for sauces?

Struggling with slow, messy, and inconsistent sauce filling? Wondering if there’s a better way to package your delicious creations?

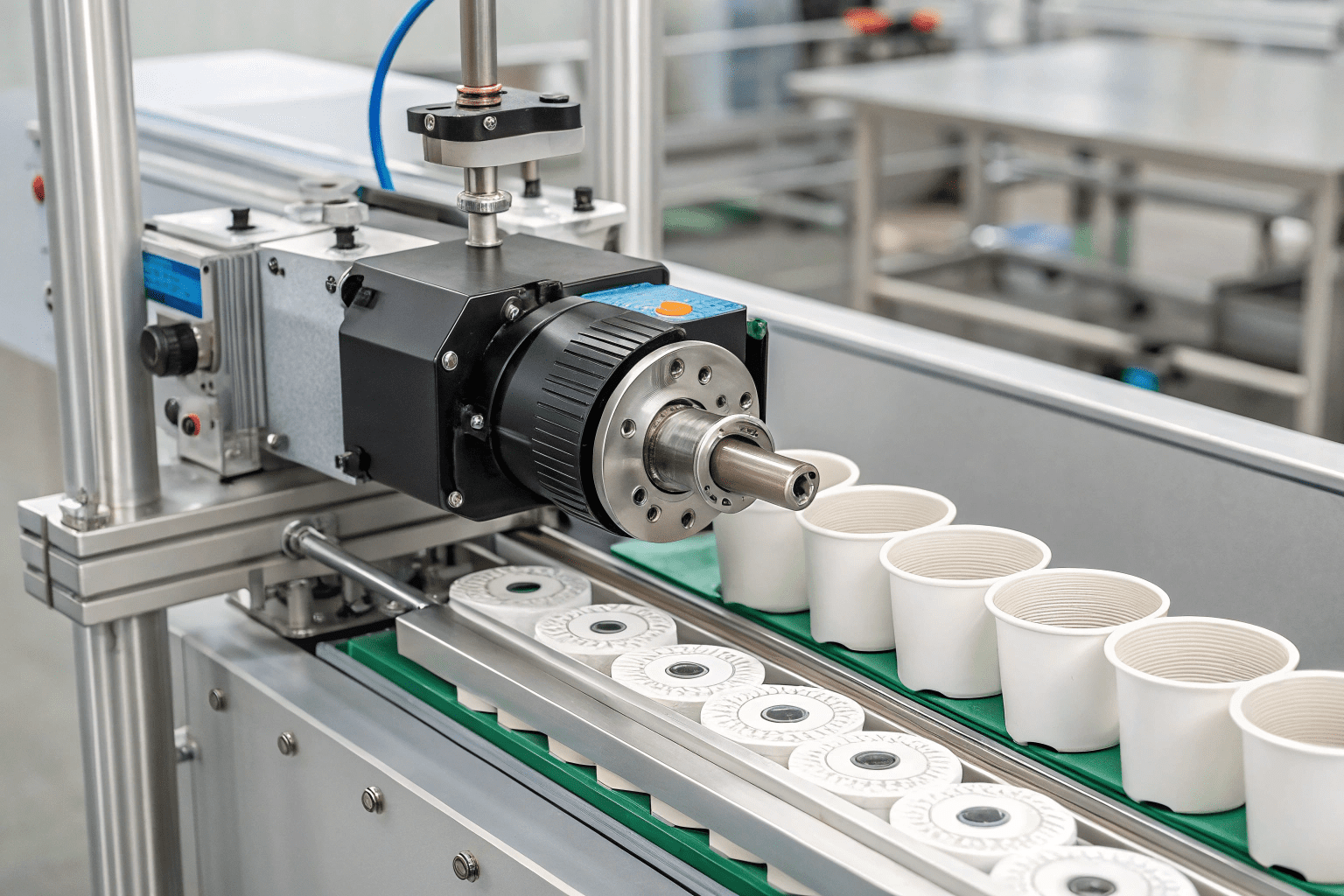

Cup filling machines automate the process of filling cups with liquids, pastes, and semi-solids, offering speed, accuracy, and hygiene. For sauces, this means reduced waste, faster production, and better product consistency.

Why are high-speed filling machines a game-changer for sauce production?

Problem: Manual filling is slow, labor-intensive, and often leads to spills and inconsistencies. Is there a way to speed things up without sacrificing quality?

High-speed filling machines can fill thousands of cups per hour. This boosts output, lowers labor costs, and keeps your sauce quality perfect.

High-Speed Filling

Think about a busy kitchen. Many hands make light work, but they also cost money. A high-speed filling machine1 does the work of many people, but faster and more consistently.

Reduced Labor Costs

Fewer people on the filling line means lower labor costs. This saved money can be used for other things, like growing your business or buying better ingredients.

Increased Production Volume

| Filling Method | Output (Cups/Hour) | Labor Cost | Product Waste |

|---|---|---|---|

| Manual Filling | ~500 | High | Up to 5% |

| Semi-Automatic Filling | ~1,000-2,000 | Medium | Up to 2% |

| Fully Automatic Filling | ~2,000-70,000+ | Low | Less than 1% |

As you can see, an automatic machine fills more cups, costs less in labor, and wastes less sauce. This means more profit for you. Also, it meets increased demand.

How does accurate filling lead to less product waste?

Tired of inconsistent fill levels and messy spills? It’s not just annoying – it’s costing you money!

Filling machines deliver precise amounts of sauce every time. This means less waste, better-looking products, and happier customers.

Accurate Filling

Imagine filling hundreds of cups by hand. Some will be overfilled, some underfilled. A machine doesn’t get tired. It fills each cup exactly the same.

Minimize Product Waste

Overfilling wastes sauce. Underfilling means your customers aren’t getting what they paid for. Accurate filling fixes both problems.

Consistent Product Quality

Every cup looks the same. Every cup has the right amount of sauce. This makes your product look professional and keeps customers happy.

Machines do this with different technologies:

- Volumetric Filling2: Measures a specific volume of sauce. Best for sauces that always flow the same way.

- Piston Filling3: Uses a piston, like a syringe. Good for thick sauces or sauces with chunks.

- Weight Filling4: Fills based on weight. Very accurate, especially for expensive sauces.

- Flow Meter Filling: Measures how much sauce flows through. Great for filling very quickly.

Why is the versatility of filling machines important for sauce businesses?

Do you dream of launching new sauce flavors or trying different cup sizes? But feel stuck with your current setup?

Many filling machines can handle different sauces and cup sizes. This lets you experiment and grow without buying new equipment.

Adapt to change

Markets change. New sauces become popular. Filling machines let you keep up without big changes.

Introduce New Products

Want to try a spicy version of your sauce? Or a smaller "snack size" cup? A versatile machine makes this easy.

Different Filling Principles.

Inline fillers:

Cups move along a straight line. Simple and often less expensive.

Rotary fillers.

Cups move in a circle. Faster and more efficient for high-volume production.

No significant equipement changes.

Most of the machines are customized following customer requirements. Change some parts of the mold and adjust the filling head, is enough.

But, remember, these machines aren’t perfect:

- Cost: They can be expensive to buy.

- Maintenance: They need regular cleaning and care.

- Changeover: Switching between sauces or cups can take time.

- Space: Some machines are very big.

How does hygienic design impact food safety in sauce production?

Worried about keeping your sauces safe and your customers healthy? Food safety is non-negotiable, right?

Cup filling machines are designed for easy cleaning and sanitation. This reduces the risk of contamination and protects your brand.

Hygienic Design:

Sauce production demands the highest standards of cleanliness. Cup filling machines, particularly those used in the food industry, are built with this in mind.

Preventing Contamination:

- Material: Most of the machines parts touching with the material directly use food-grade materials5.

- Smooth Surfaces: Machines feature smooth, non-porous surfaces to prevent sauce buildup and bacterial growth.

- Easy Cleaning: Designs allow for quick disassembly and thorough cleaning, minimizing the risk of contamination.

Protecting Consumers:

- Food Safety Compliance: Hygienic design helps sauce producers meet strict food safety regulations.

- Reduced Risk: Minimizes the chance of foodborne illnesses, protecting consumers and building trust.

Safeguarding Reputation:

- Brand Image: A commitment to hygiene enhances a brand’s reputation for quality and safety.

- Consumer Confidence: Customers are more likely to choose products from companies they trust to prioritize food safety.

- Avoiding Recalls: Preventing contamination reduces the risk of costly product recalls and damage to the brand’s image.

Conclusion

Cup filling machines offer many benefits for sauce producers: speed, accuracy, versatility, and hygiene. They can help you make more sauce, waste less, and keep your customers safe.

-

Explore the advantages of high-speed filling machines to enhance efficiency and profitability in your production line. ↩

-

Explore this link to understand how Volumetric Filling works and its benefits for consistent sauce production. ↩

-

Learn about Piston Filling and its advantages for thick sauces, ensuring quality and efficiency in production. ↩

-

Discover the accuracy of Weight Filling and why it’s ideal for high-value sauces, enhancing your production process. ↩

-

Understanding food-grade materials is crucial for ensuring safety and compliance in food production. Explore this link to learn more. ↩