Can a cup filling and sealing machine be customized for specific needs?

Having trouble finding the right machine for your product? You see a popular product and want a machine, but you don’t know where to start. It’s a common problem.

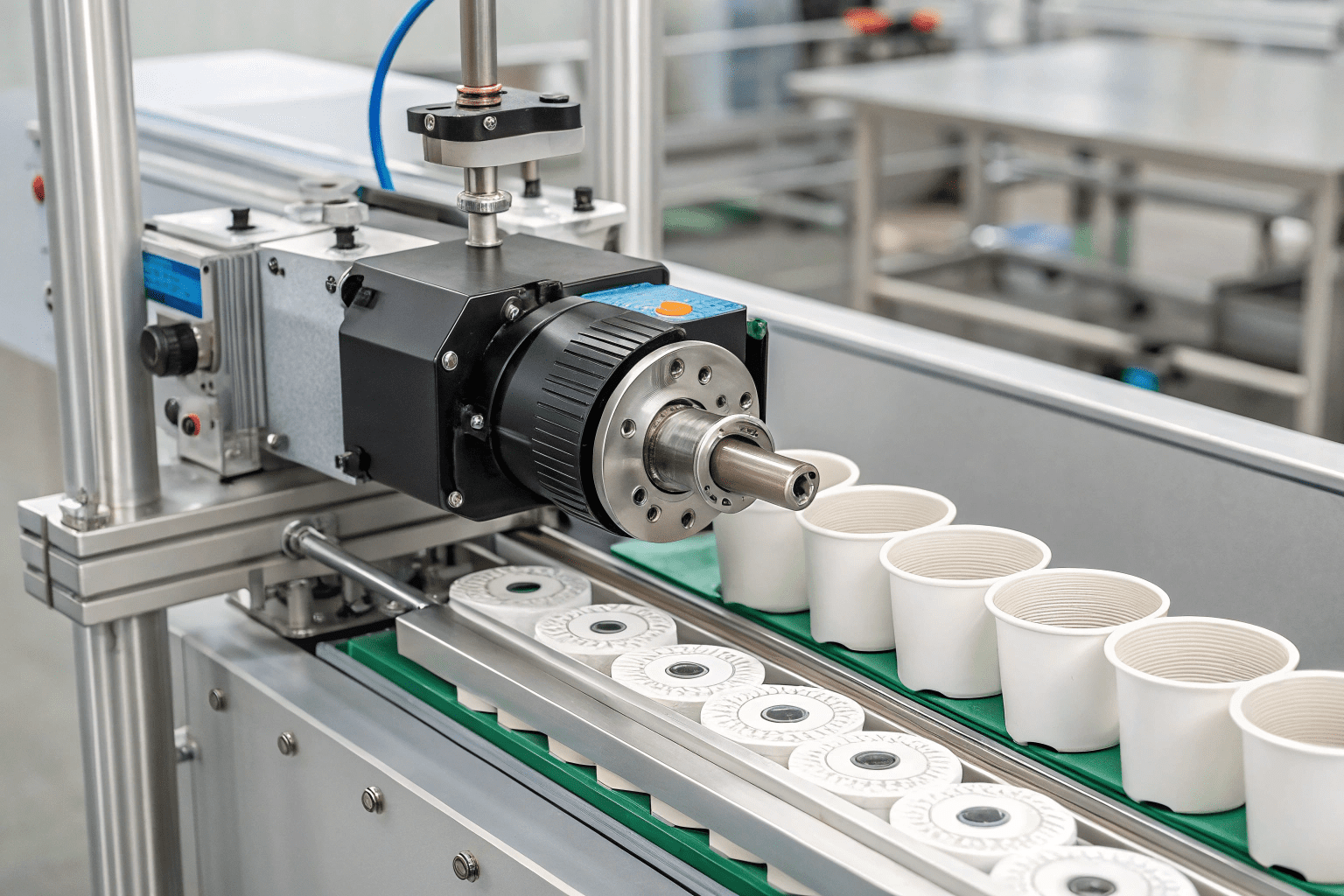

Yes, cup filling and sealing machines are mainly customized. Things like cup size, production volume, and filling material are some of the main factors used to make a filling and sealing machine.

Customization is key in this industry. So, let’s go through the key points. This will help you better.

Are cup sizes a significant factor in machine customization?

Struggling to fit your unique cup design into standard machines? It feels like a square peg in a round hole, right? This is a big problem.

Cup sizes are a big factor. Machines are adjusted to match the exact dimensions of the cups or bottles provided by the client.

We tailor each machine based on client specifications. The first step is always getting a sample. Here’s how we break it down:

Cup/Bottle Dimensions

| Feature | Description |

|---|---|

| Measurement1 | We precisely measure the diameter, height, and shape of your cup or bottle. |

| Material | We consider the material of your container (plastic, glass, etc.) because it affects how the machine handles it. |

| Design Input2 | If you have specific design requirements, such as unique shapes or features, we integrate these into the machine’s design to ensure smooth operation without damaging the containers during filling and sealing. |

| Custom Tooling3 | The machine may have holding trays, sealing heads, and conveyor parts, and other parts have to made for the specific cup or bottle. |

It is not just about making the machine fit. Making sure every part of the machine works perfectly with your cup is the goal.

How does the desired production volume affect machine customization?

Worried that the machine won’t keep up with your growing demands? It’s like being stuck in the slow lane when you need to speed up, frustrating, right?

Production volume is crucial. Machines are built to meet specific hourly output needs, ranging from 2,000 to 70,000 pieces per hour, depending on the model.

The production capacity is adjusted according to the needs. Here’s how it affects the machine.

Production Capacity

| Aspect | Details |

|---|---|

| Hourly Output4 | We determine the number of cups or bottles the machine needs to fill and seal per hour. This can range from a few thousand to tens of thousands. |

| Machine Speed | The speed of the machine is calibrated to match the desired output. Faster speeds are required for higher volumes. |

| Automation Level5 | Higher production volumes often require fully automated systems. This includes automatic cup dispensing, filling, sealing, and even packing. |

| Scalability6 | We design machines that can be scaled up. If your production needs increase in the future, the machine should be able to accommodate that growth, potentially with additional modules or upgrades. |

It all comes down to how many you want to make per hour. The machine should fit your business, both now and in the future.

Is the type of filling material important for machine customization?

Does your product seem too unique for standard filling machines? Feeling like your special filling needs are being ignored? It is difficult.

The type of filling material is very important. Machines must be compatible with liquids, creams, pastes, or granules, like jelly, yogurt, chocolate, or juice.

The machine is made to handle your specific material.

Filling Material Compatibility

| Material Type | Description |

|---|---|

| Liquids | Machines can be configured for free-flowing liquids7 like juice and milk, ensuring accurate and spill-free filling. |

| Creams/Pastes | For thicker substances8 like yogurt or jam, the machine uses pumps and nozzles designed to handle the viscosity without clogging. |

| Granules | Products like jelly or chocolate granules require specific dispensing mechanisms[^9] to ensure even distribution and prevent damage to the product. |

| Temperature | Some products need to be filled at specific temperatures. Some may need cooling, others may need heating. |

It’s about matching the machine to the product perfectly. So the product stays in good condition.

Conclusion

Cup filling and sealing machines are customized. Cup size, filling material, and how many you want to make are very important. All are considered in the making.

-

Understanding measurement techniques can enhance your container design process and ensure compatibility with machinery. ↩

-

Learning about design input can help you create machines that better meet your unique operational needs and enhance productivity. ↩

-

Exploring custom tooling can reveal how tailored solutions optimize production and reduce waste in packaging processes. ↩

-

Understanding hourly output helps optimize production efficiency and meet business demands effectively. ↩

-

Exploring automation levels can reveal how to enhance productivity and reduce labor costs in manufacturing. ↩

-

Learning about scalability ensures your machinery can grow with your business, preventing future constraints. ↩

-

Explore this link to discover top machines designed for efficient and spill-free filling of liquids like juice and milk. ↩

-

Find out about specialized dispensing mechanisms that ensure even distribution of granules without damaging the product. ↩