Can Cup Filling and Sealing Machines Handle Different Types of Lids (Foil, Plastic, etc.)?

Having the right packaging is super important for food businesses. It keeps things fresh and looks good on the shelf. But what about the lids? Can one machine really seal all kinds?

Yes, cup filling and sealing machines can often handle various lid types like foil and plastic. Food manufacturers pick lids based on product needs and cost, so machines are usually made to be flexible. The sealing part works for most lids, but the lid dispenser is changed to fit each kind.

It’s a common question, and it makes sense to wonder. Let’s get into how these machines work with different lids.

Are Foil Lids Compatible with Most Cup Sealing Machines?

Foil lids are everywhere, especially on things like yogurt and single-serve snacks. They’re great for keeping things airtight. But, do they need a special machine?

Generally, yes, foil lids work well with most cup sealing machines. Because, they are commonly used for an airtight seal. But the machine’s lid dispenser might need adjustment to work best with foil.

Let’s look closer at how these machines handle foil. Think about it – foil is thin and can be delicate.

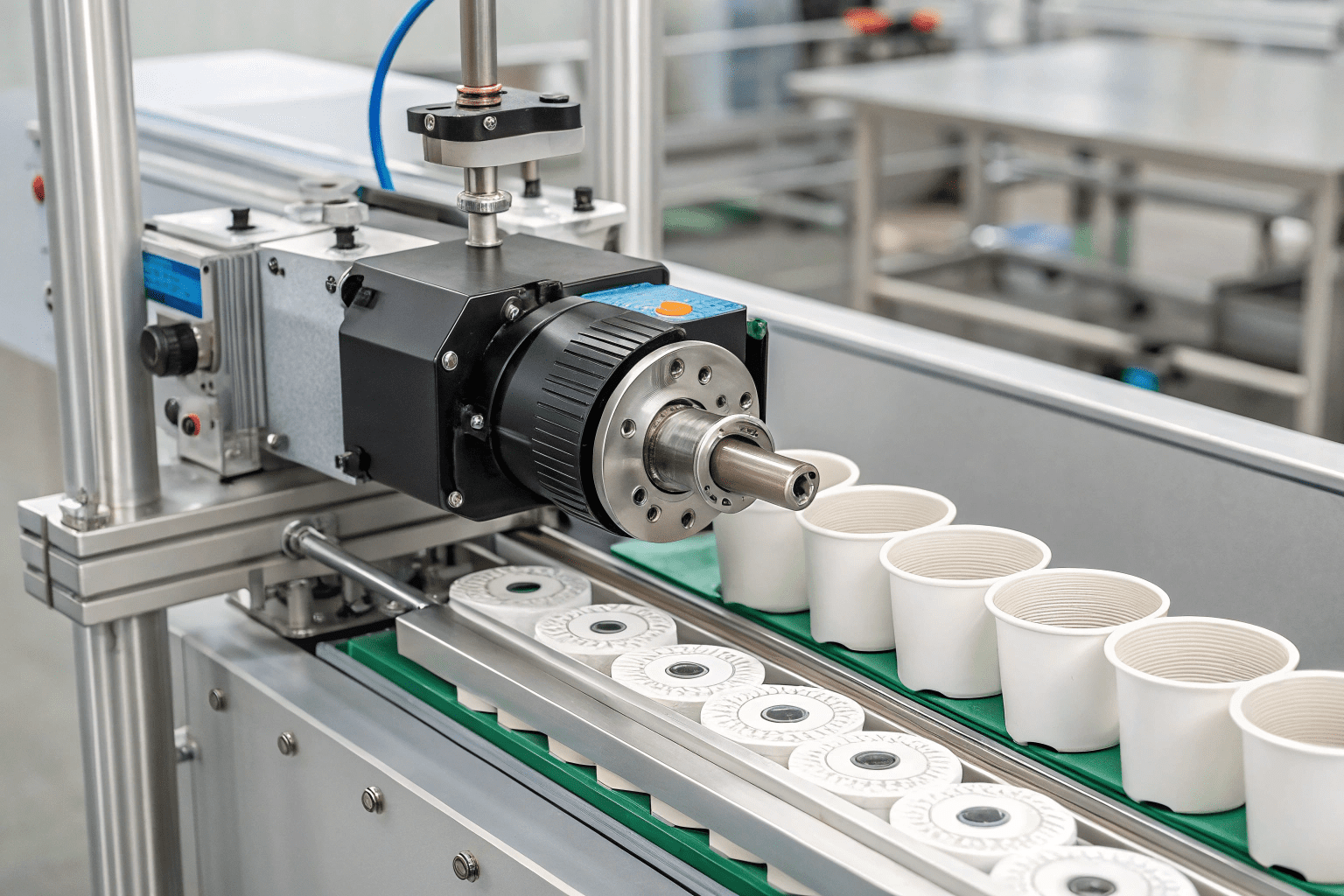

Foil Lid Handling: Precision is Key

Foil lids are popular because they create a strong barrier1. They keep air and moisture out. This is important for keeping food fresh.

| Feature | Description | Benefit |

|---|---|---|

| Material | Thin aluminum | Lightweight, cost-effective |

| Sealing | Heat-sealed to the cup rim | Creates an airtight, tamper-evident seal2 |

| Dispensing | Requires precise handling3 to avoid damage | Ensures proper placement and sealing |

| Compatibility | Works with various cup materials (plastic, paper) | Versatile for different product packaging |

The sealing part of the machine uses heat and pressure. This melts a coating on the foil, sticking it to the cup. The machine needs to control the temperature and pressure. The dispenser, however, is different. It needs to pick up and place the foil gently.

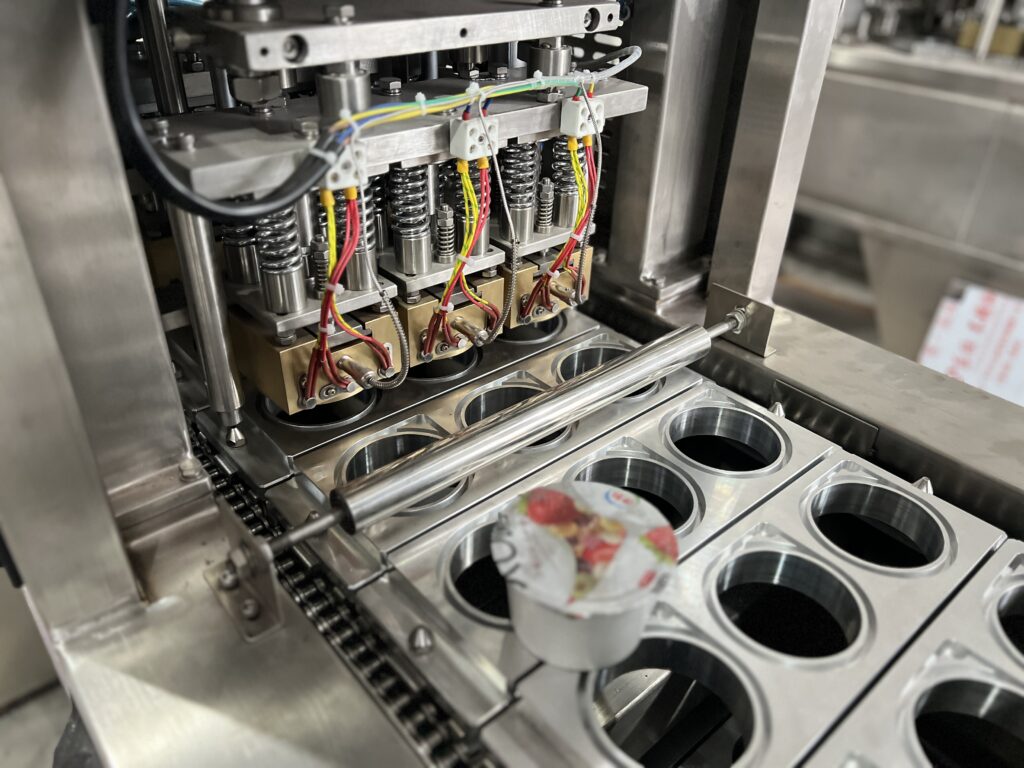

How Do Machines Manage Plastic Lids?

Plastic lids are also super common. They’re sturdy and come in many shapes. Can the same machine that seals foil also handle these?

Often, yes, machines that handle foil can also seal plastic lids. The heat-sealing process is similar. But the part that grabs and places the lids will be different because plastic lids are different from foil.

Plastic lids are usually more rigid than foil. They might be snap-on or have a film that peels off.

Plastic Lid Versatility

Plastic lids offer different advantages. They can be resealable, which is great for some products.

| Feature | Description | Benefit |

|---|---|---|

| Material | Various plastics (PP, PET, etc.) | Durable, can be clear or colored |

| Sealing | Can be heat-sealed4, snap-on5, or use a separate sealing film6 | Offers flexibility in closure type |

| Dispensing | Needs a system designed for the specific lid shape and size | Ensures lids are picked and placed accurately |

| Compatibility | Works with various cup materials | Can be used for many different products |

The sealing method might be a bit different. Some plastic lids use a separate film. This film is heat-sealed to the cup. Others snap on. The machine needs the right parts to handle each type. Think of it like changing tools for different jobs.

What About Other Lid Materials?

Foil and plastic are the most common, but what about others? Some products use paper-based lids or even metal.

While less common, some machines can be adapted for other lid materials. Paper-based lids might need different heat settings. However, the basic principle of the sealing process can stay, but the dispensing might still need special attention.

These materials might need slightly different handling.

Adapting to Different Materials

The key is understanding how each material behaves. How does it react to heat? How easily does it tear?

| Material | Characteristics | Sealing Considerations |

|---|---|---|

| Paper-based | Can be coated for moisture resistance | May need lower heat, careful pressure |

| Metal | Durable, often used for canned goods | Requires specialized crimping or sealing tools |

| Composite | Combination of materials (paper + foil, etc.) | Needs settings adjusted for each component |

The machine’s settings can often be adjusted. Temperature, pressure, and even the timing can be changed. But, the machine needs to be designed to allow these changes.

Conclusion

Cup filling and sealing machines are built to be flexible. They can usually handle foil, plastic, and sometimes even other lid types. The sealing technology is adaptable, but the lid dispenser needs changing.

-

Understanding strong barriers in food packaging can help you choose the best options for freshness and safety. ↩

-

Learn about the technology behind airtight seals to ensure your food remains uncontaminated and fresh. ↩

-

Discover the significance of precise handling in packaging to maintain product integrity and quality. ↩

-

Explore the advantages of heat-sealed packaging, including its durability and effectiveness in preserving product freshness. ↩

-

Learn about snap-on lids, their ease of use, and how they provide a secure closure for various products. ↩

-

Discover the role of sealing film in packaging, its applications, and how it enhances product protection. ↩