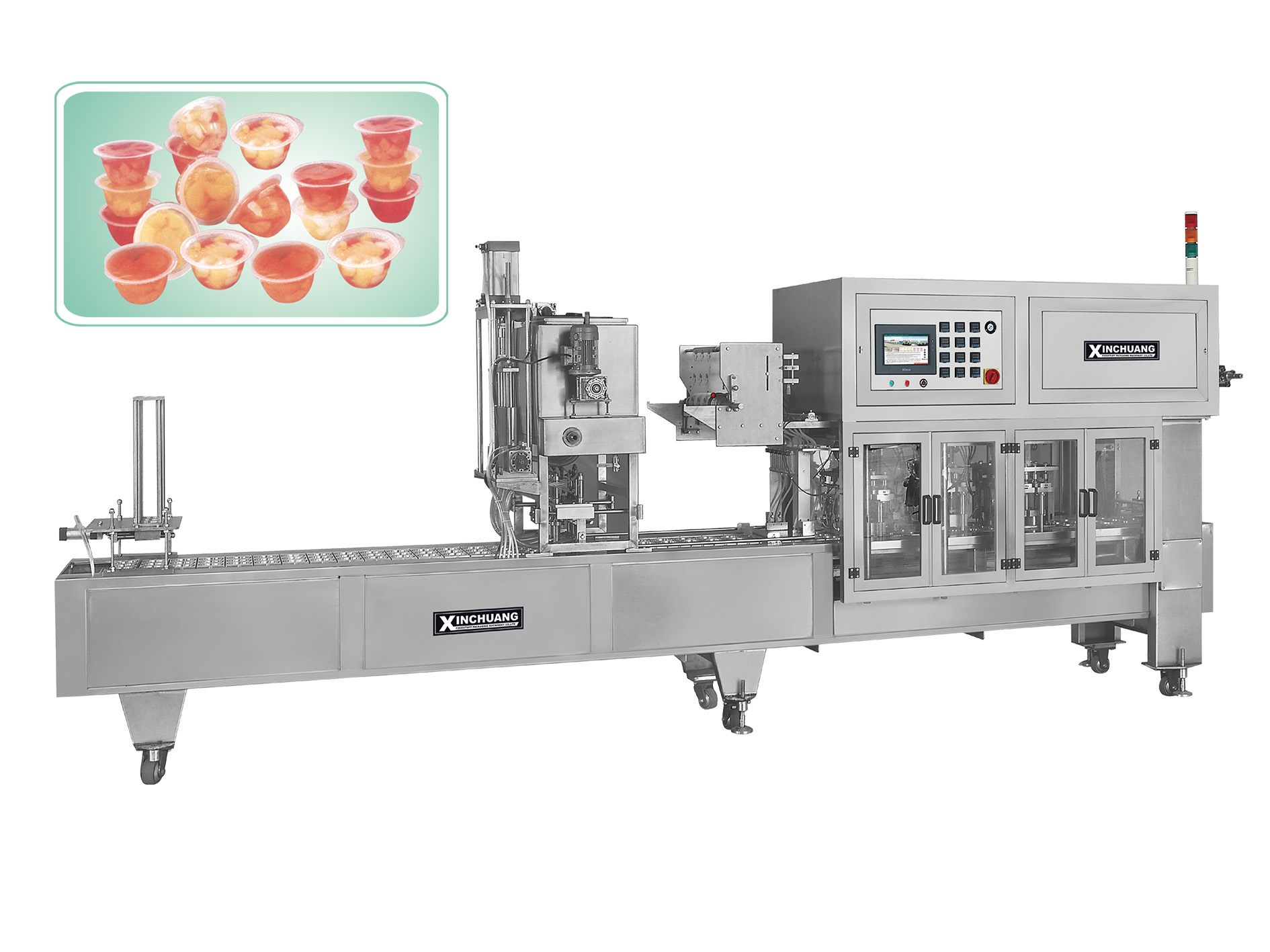

CFD Series Cup Auto Filling and Sealing Machine

Your trusted source for Filling and Sealing Machine

CFD-10 Cup Water Auto Filling & Sealing

CFD 2-color Jelly Auto Filling & Sealing

CFD-6 Latte-Art Auto Filling Machine

CFD-12 Jam Auto Filling & Sealing

CFD-16 Honey Auto Filling and Sealing

CFD-48 Chocolate Auto Filling and Sealing

Endless product possibilities with our Filling and Sealing Machine

Reliable Filling and Sealing Machine Maufacture

Our machines utilize German and Japanese electrical components, paired with our proprietary operating system. This combination ensures ease of use for our customers while enhancing machine stability and longevity.

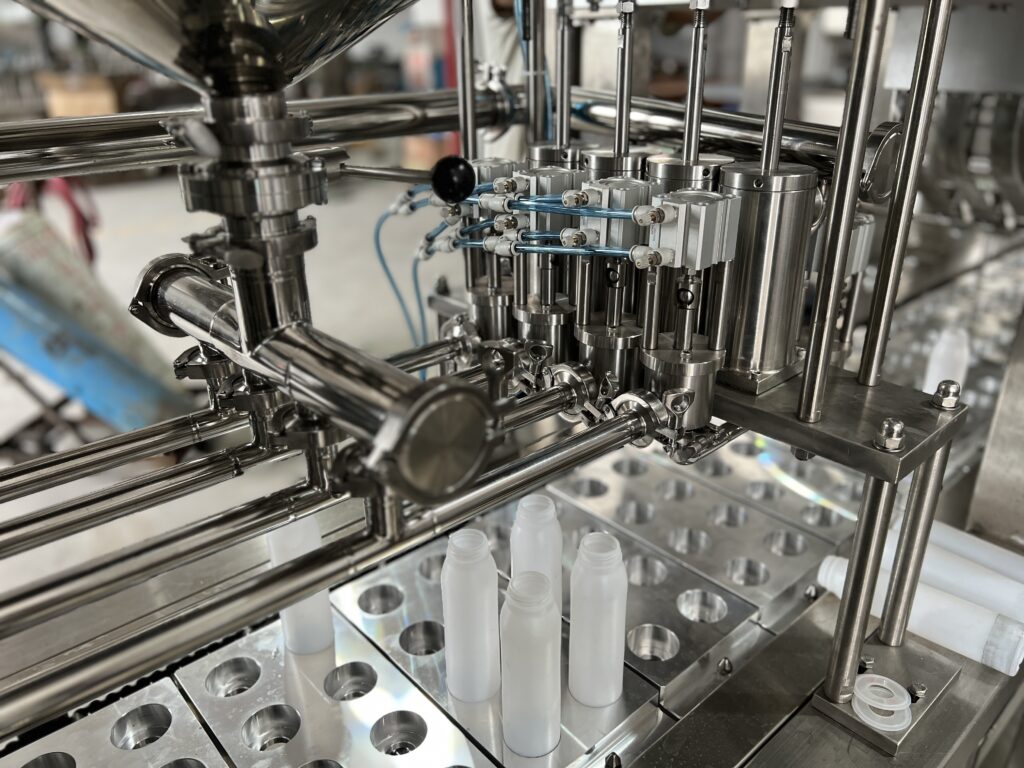

Molds are custom-made to fit the specific cup sizes provided by our clients. We also customize the number of lanes on the machine to match their desired production output. All components are manufactured using high-specification aluminum

Proper sealing is essential for maintaining product freshness, preventing leaks, and ensuring food safety. The machine needs to be calibrated to the correct cup size to create an airtight seal.

The filling method determines how accurately and consistently the machine dispenses the product into each container. Different methods are suited for different product types and desired accuracy levels

The entire machine is constructed with international standard 304 stainless steel, with the option to upgrade to 316 stainless steel. We offer different options based on your budget, with higher-grade materials extending the machine's lifespan

Equipped with multiple imported machine tools and machining centers, we maximize machining precision and ensure complete control throughout the entire production process, providing you with superior service.