How does water cup filling machine work?

When you want to start a beverage business, you worry about how to fill and seal water cups quickly and safely. This is a real problem for many people.

A water cup filling machine helps you fill and seal cups fast. It makes sure every cup is clean, full, and safe to drink. This is how many factories make drinks you see in stores.

If you want to know how these machines work, keep reading. I will share what I have learned from my own experience. I will also tell you what makes a good water cup filling machine.

What do you need before using a water cup filling machine?

You need to get the right cups and sealing film before you start. Many people do not know this and waste time later.

You must buy plastic cups made from PP material. You cannot use just any cup. The machine is made for these cups. If you use the wrong cup, it will not seal well. You also need to check what kind of sealing film you have. If you use nylon film, the machine needs one kind of film holder. If you use aluminum film, it needs a different holder. This is very important.

I learned this the hard way. Once, a client brought PET cups and tried to use them. The machine could not seal them. The cups melted or did not stick. We had to stop and get the right PP cups. The sealing film is also tricky. Nylon film and aluminum film need different holders. If you use the wrong one, the film will not feed right. The machine will jam or waste film. Here is a table to help you choose:

| Cup Material | Can Use? | Notes |

|---|---|---|

| PP | Yes | Best for sealing |

| PET | No | Melts, does not seal |

| PS | No | Not recommended |

| Film Type | Holder Needed | Notes |

|---|---|---|

| Nylon | Nylon film holder | For flexible sealing |

| Aluminum | Aluminum film holder | For strong, airtight seal |

Always check with your supplier before you buy cups or film. This saves you time and money.

How does the filling process work in the machine?

You want every cup to have the right amount of water. Too much or too little is not good. The machine must be easy to adjust.

My machine uses gravity to fill each cup. This is called gravity self-flow filling. It is simple and clean. You can adjust the filling volume any time. If you want to fill 200ml, you set it. If you want 250ml, you change the setting. The water flows down by itself. There is no pump to break or clean. This makes the machine easy to use and fix.

Why is gravity self-flow filling better?

I have seen many machines with pumps. Pumps can break. They are hard to clean. Gravity self-flow is simple. Water flows from a tank above. You open or close a valve to set the amount. Here is how it works:

| Filling Method | How it Works | Pros | Cons |

|---|---|---|---|

| Gravity self-flow | Water flows down | Simple, clean, easy | Needs height |

| Pump filling | Uses a pump | Fast, precise | Hard to clean, can break |

You can change the filling volume by turning a knob. This is good for different cup sizes. You do not need a technician. Anyone can do it.

How does the machine make sure the cups do not leak?

No one wants a leaking cup. Leaks make a mess and waste money. The sealing must be strong.

My machine seals each cup two times. The first seal makes sure the film sticks. The second seal presses harder. This double seal keeps water inside. Even if you shake the cup, it will not leak. I tested this myself. I filled cups, sealed them, and turned them upside down. No leaks.

Why is double sealing important?

I remember a client who had problems with leaks. Their old machine sealed only once. Some cups leaked. After switching to my double-seal machine, the problem stopped. Here is a simple table:

| Sealing Method | Leak Risk | Notes |

|---|---|---|

| Single seal | Higher | May leak if not perfect |

| Double seal | Low | Very safe, no leaks |

Double sealing gives you peace of mind. You do not need to worry about returns or complaints.

How do you pack the cups after filling and sealing?

After filling and sealing, you need to pack the cups fast. Doing it by hand is slow and tiring.

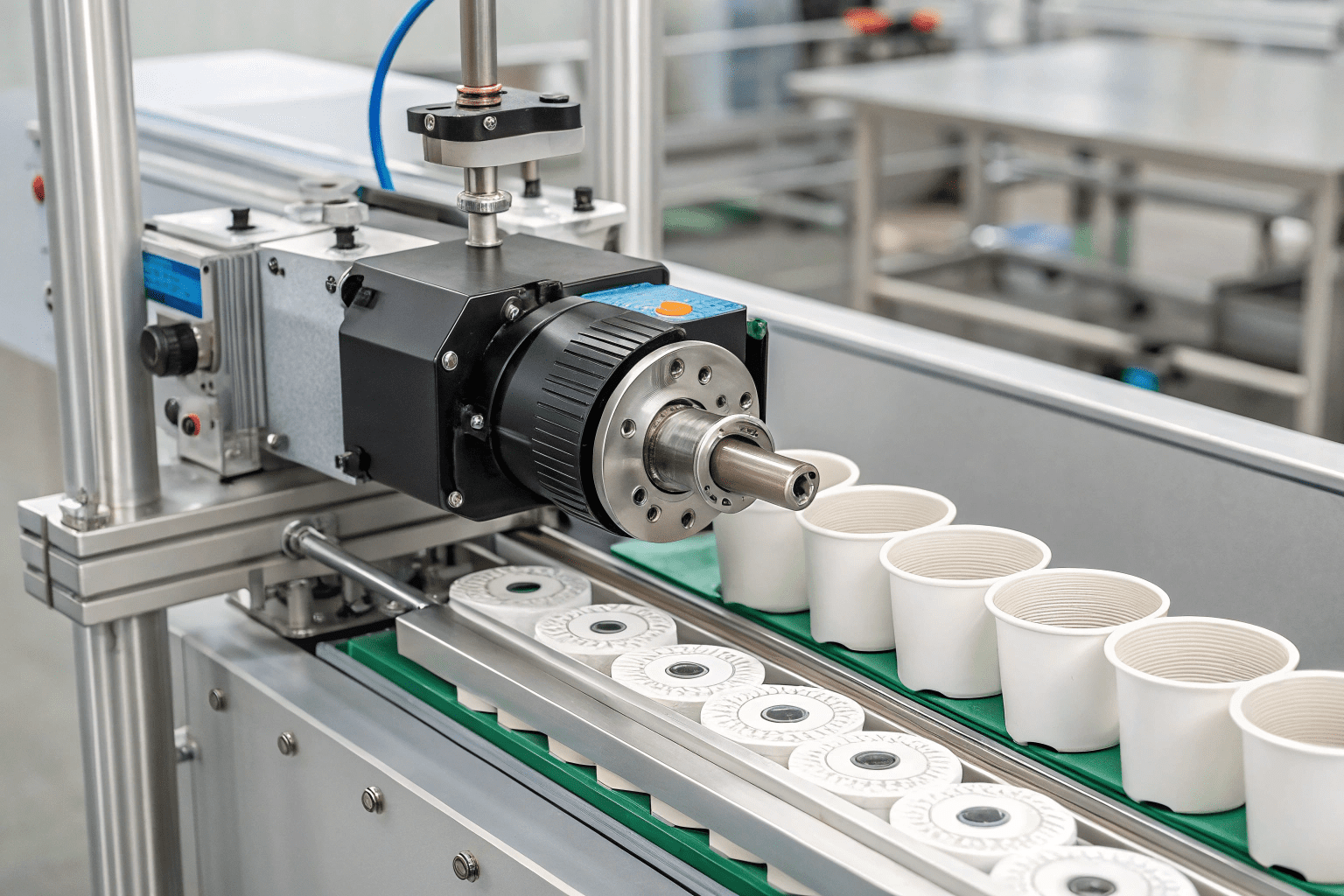

My machine can add a conveyor belt after the cups come out. The cups move on the belt. Workers can pack them into boxes easily. This saves time and keeps the line moving. You can also connect the belt to other machines, like a shrink wrapper or box packer.

Why use a conveyor belt?

I used to see workers pick up cups one by one. It was slow. With a conveyor belt, the cups move by themselves. Workers just stand at the end and pack. Here is a table:

| Packing Method | Speed | Labor Needed | Notes |

|---|---|---|---|

| By hand | Slow | More | Tiring, not efficient |

| Conveyor belt | Fast | Less | Easy, saves time |

A conveyor belt makes your factory look modern. It also helps you make more cups every hour.

Conclusion

A good water cup filling machine makes your work easy, fast, and safe. It helps you grow your business.