How is Coffee Capsule Produced by Filling and Sealing Machine?

Are you frustrated with stale coffee that’s lost its flavor? You’re not alone. Many coffee lovers struggle with preserving freshness, but modern coffee capsules solve this problem through precise manufacturing processes.

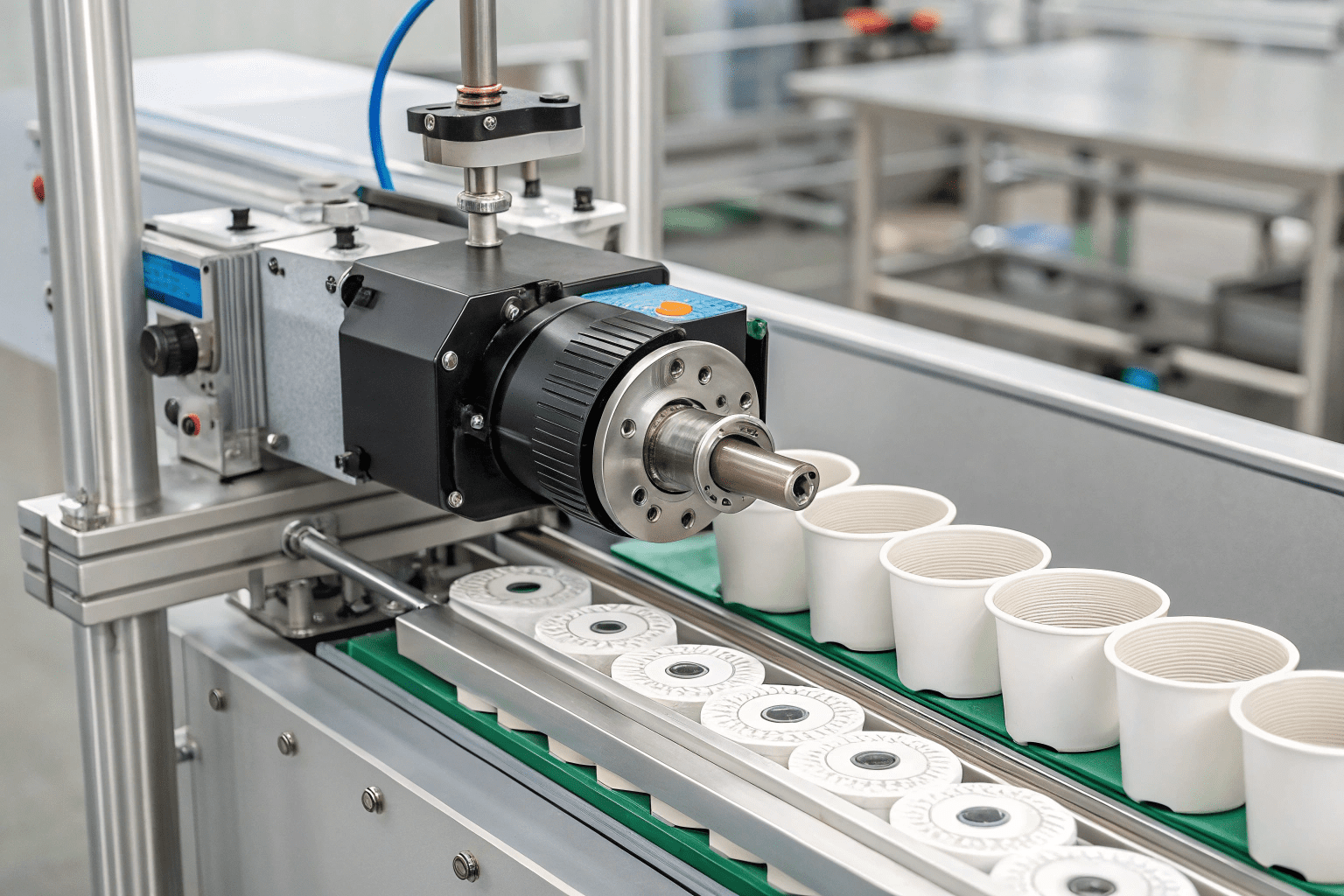

Coffee capsules are produced using specialized K-cup filling and sealing machines that automate the entire process. These machines drop empty cups, precisely fill them with coffee grounds, and seal them with aluminum film, creating an airtight package that preserves freshness for 12-24 months.

I’ve been in the food packaging machinery business for years, and coffee capsule production technology has revolutionized how we enjoy coffee. Let me walk you through the fascinating process of how these convenient pods are made and how they keep your coffee fresh for so long.

How Is The Coffee Pod Made?

Do you wonder what happens in factories before those convenient coffee pods reach your kitchen? Many coffee drinkers enjoy the convenience but rarely consider the sophisticated manufacturing process behind each perfectly sealed capsule.

Coffee pods are manufactured using specialized K-cup filling and sealing machines that automate the entire production process. These machines precisely measure coffee grounds, fill pre-formed cups, and seal them with aluminum film, creating an airtight barrier that preserves freshness and flavor.

The manufacturing process for coffee capsules is actually quite fascinating when you look at the details. Each step is carefully designed to ensure quality and consistency.

The Step-by-Step Production Process

-

Cup Formation and Dropping

- Pre-formed cups are loaded into the machine

- Cups are automatically dispensed one-by-one onto the conveyor

- Quality checks ensure each cup is perfectly shaped

-

Precise Filling

- Coffee grounds are measured with exact precision

- Filling heads deposit the perfect amount of coffee

- Different coffee varieties require specific calibration

-

Sealing Technology

- Aluminum film is heat-sealed to the cup rim

- Creates airtight barrier crucial for freshness1

- Nitrogen flushing often removes oxygen before sealing

-

Final Processing and Output

- Sealed capsules undergo quality inspection

- Defective capsules are automatically rejected

- Finished products are counted and packaged

What makes these machines so valuable to manufacturers is their customizable production capacity2. Modern K-cup filling and sealing machines3 offer:

| Production Capacity | Machine Type | Ideal For |

|---|---|---|

| 2,000-10,000/hour | Small-scale | Boutique coffee brands |

| 10,000-30,000/hour | Mid-range | Regional distributors |

| 30,000-70,000/hour | Industrial | National coffee brands |

This scalability4 allows coffee producers of all sizes to find equipment that matches their production needs without sacrificing quality or freshness.

How Long Do Coffee Capsule Stay Fresh?

Have you ever found an old coffee capsule and wondered if it’s still good? Coffee lovers often worry about wasting money on expired pods, but properly sealed capsules have a surprisingly long shelf life.

When manufactured correctly with high-quality sealing technology, coffee capsules can stay fresh for 12-24 months. The aluminum film seal creates an airtight barrier that protects coffee grounds from oxygen, moisture, and light—the three main factors that cause coffee deterioration.

The impressive shelf life of coffee capsules isn’t just convenient—it represents a significant technological achievement in food preservation. The sealing quality is absolutely crucial to maintaining this freshness, which is why manufacturers invest in advanced machinery.

Factors Affecting Coffee Capsule Freshness

The freshness retention of coffee capsules depends on several key factors that manufacturers must carefully control during production:

-

Sealing Quality5

The most critical factor is the integrity of the seal between the aluminum film and the cup. Even microscopic gaps can allow oxygen to enter, starting the degradation process. Advanced K-cup filling and sealing machines use precise temperature and pressure controls to create perfect seals consistently. -

Packaging Materials6

Not all capsule materials are created equal. While some manufacturers use basic plastic cups, others employ specialty polymers with enhanced oxygen barrier properties. The aluminum film used for sealing also varies in thickness and quality, with premium films offering superior protection. -

Processing Environment7

The factory environment during production plays a significant role in freshness. Many high-end manufacturers use controlled atmospheres with reduced oxygen levels during the filling and sealing process. Some even inject nitrogen into the capsules before sealing, displacing oxygen and further extending shelf life.

| Storage Condition | Expected Shelf Life | Quality Impact |

|---|---|---|

| Room temperature (sealed) | 12-24 months | Optimal freshness |

| Refrigerated (sealed) | 24-36 months | Extended freshness |

| Improperly sealed | 1-3 months | Rapidly deteriorates |

| After seal breakage | 1-2 weeks | Significantly compromised |

By investing in quality manufacturing equipment, coffee producers can guarantee consistency not just in taste but in the longevity of their products. For consumers, this means coffee capsules purchased today will deliver the same excellent flavor months down the road, providing both convenience and reliable quality.

Conclusion

Coffee capsules represent an amazing blend of convenience and preservation technology. Through automated filling and sealing machines, manufacturers create perfectly portioned coffee that stays fresh for up to two years, ensuring you always enjoy the perfect cup.

-

Understanding the role of airtight barriers can enhance your knowledge of food preservation and packaging technology. ↩

-

Understanding customizable production capacity can help manufacturers optimize their production processes and meet market demands effectively. ↩

-

Exploring K-cup filling and sealing machines can provide insights into their technology and benefits for coffee producers. ↩

-

Learning about scalability in manufacturing can help businesses adapt to changing demands and improve efficiency. ↩

-

Understanding sealing quality is crucial for ensuring product freshness and preventing degradation. Explore this link to learn more about its significance. ↩

-

Discover the impact of different packaging materials on coffee freshness and quality. This resource will enhance your knowledge on the subject. ↩

-

The processing environment is vital for maintaining freshness. This link will provide insights into how it influences shelf life and quality. ↩