How to Choose the Right Yogurt Cup Filling Machine for Your Business?

Struggling with product spoilage? A contaminated filling process can destroy your yogurt’s quality and your brand’s reputation. Choosing the right machine is the key to protecting your business.

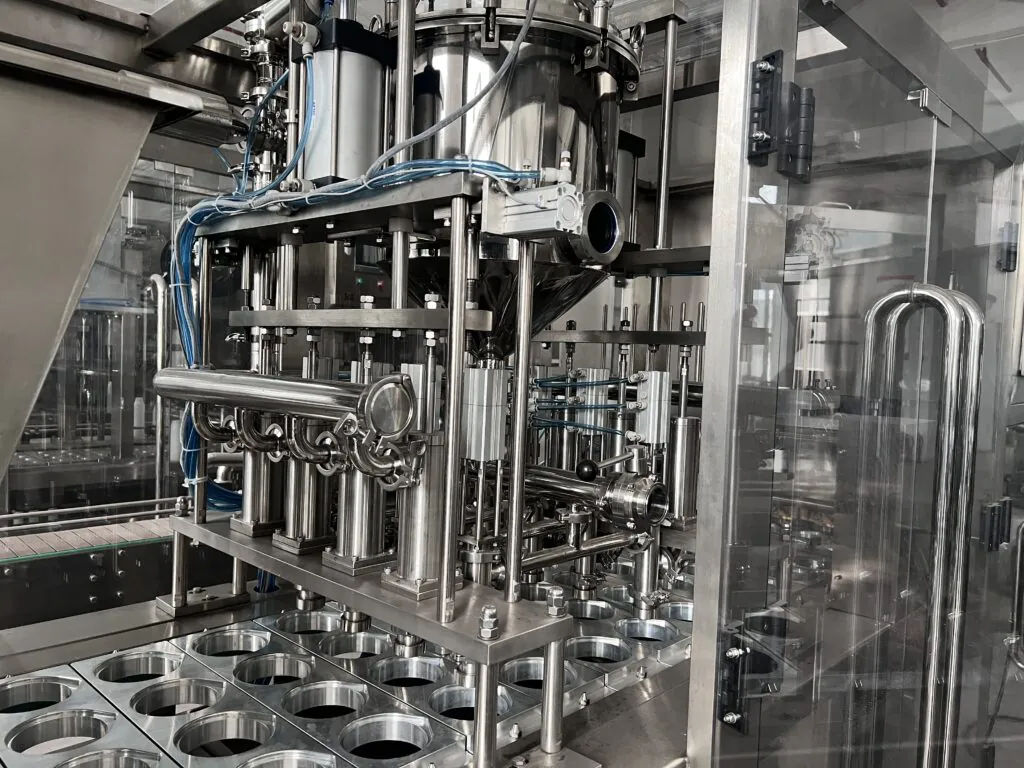

To choose the right yogurt cup filling machine, you must prioritize hygiene. Look for essential features like a fully enclosed design, a CIP cleaning system, a laminar flow hood for air purification, and UV sterilization for both cups and film. These features guarantee a safe and high-quality product.

I’ve been in this business for a long time, and I’ve seen many companies focus only on speed or initial cost. But when we talk about a sensitive product like yogurt, hygiene is not just a feature; it’s the most important thing. It’s the foundation of product safety, shelf life, and customer trust. A mistake here can lead to recalls that can end a business. So, what specific features should you really be looking for to avoid these problems? Let’s break it down so you can make a smart, safe choice for your dairy business.

Why are sanitation and hygiene the top priorities in yogurt cup filling machine?

Are you underestimating the risk of bacteria in your yogurt production? A single oversight can lead to huge losses. Contamination means shorter shelf life, unhappy customers, and serious food safety issues.

Sanitation is critical because yogurt is a live-culture product, which makes it very easy for unwanted bacteria to grow. A hygienic machine ensures product safety, extends shelf life, and keeps the quality and taste your customers expect. It is the foundation of a trusted dairy brand.

When you produce yogurt, you are working with a living product. The good bacteria, the probiotics, are what make yogurt healthy. But these conditions are also perfect for bad bacteria to grow. If unwanted microorganisms get into your product during filling, they can cause big problems. They can spoil the yogurt, making it taste bad or look wrong. More seriously, they can cause foodborne illness.

I once visited a customer in Algeria who was struggling with a short shelf life for his yogurt products. His team was frustrated because products were spoiling on the shelf long before the expiration date. After checking his process, we found the problem. His old filling machine was open to the factory air. This allowed airborne yeast and mold to get into the cups during the filling process. We replaced it with one of our fully enclosed machines. The problem disappeared almost overnight. His shelf life improved, waste went down, and his profits went up. This shows how important the right machine is.

Standard Machine vs. Hygienic Machine

| Feature | Standard Machine Risk | Hygienic Machine Solution1 |

|---|---|---|

| Filling Environment | Open to airborne dust and bacteria. | Fully enclosed with a laminar flow hood for purified air. |

| Hopper Cleaning | Requires manual disassembly, inconsistent cleaning. | Automated CIP (Clean-in-Place) system for thorough cleaning. |

| Packaging Materials | No pre-treatment, carries surface bacteria. | UV sterilization lamps for both cups and sealing film. |

| Product Safety | High risk of spoilage and customer complaints. | Consistent quality, long shelf life, and brand trust. |

What are the must-have features for a hygienic yogurt filler?

Feeling overwhelmed by all the technical details? It can be hard to know which machine features really matter for safety. Choosing the wrong ones means you either waste money or miss critical functions.

A must-have feature is a fully enclosed structure to prevent contamination. Also look for a CIP (Clean-in-Place) system for the material hopper, a laminar flow hood for air purification, and UV sterilization lamps for both cups and sealing film. These are the core features of a modern, safe machine.

Let’s dive deeper into each of these essential features. They all work together to create a fortress that protects your yogurt.

Fully Enclosed Design

Think of this as a cleanroom for your filling process. A fully enclosed machine, often made with stainless steel and protective glass, creates a physical barrier. It stops dust, insects, and most importantly, airborne bacteria from ever reaching your product. An open machine is like leaving food out on a counter. An enclosed machine is like keeping it in a sealed, clean container. This is your first and most basic line of defense.

CIP (Clean-in-Place) System2

Cleaning the machine is just as important as the filling process itself. A CIP system automates this. Instead of taking the material hopper apart by hand to clean it, the system circulates hot water, cleaning solutions, and sanitizers through the pipes and tank automatically. This ensures every surface is cleaned perfectly every single time. I remember a client in India who cut his cleaning time by over 70% and saw a huge improvement in his microbial test results after switching to a machine with CIP. It’s more consistent, safer for workers, and much more effective than manual cleaning.

Laminar Flow Hood and UV Sterilization3

These two features provide the final, critical steps of protection. A laminar flow hood is a special fan and filter system built into the top of the enclosed area. It pushes a constant stream of sterile, filtered air downwards. This creates positive pressure, so if there are any tiny gaps, clean air flows out, and no unclean factory air can get in. Then, right before the cup is filled and sealed, both the cup and the sealing film pass under strong UV lamps. This ultraviolet light kills any remaining bacteria on these surfaces. This double-action approach is the best way to ensure the highest level of hygiene right at the most critical moment.

How does customization affect hygiene and efficiency?

Do you think a standard, off-the-shelf machine will fit your unique yogurt and cups? It almost never does perfectly. An ill-fitting machine can lead to product drips, bad seals, and slow changeovers, which all compromise hygiene.

Customization directly impacts hygiene and efficiency. A machine made for your specific cup size and yogurt thickness ensures a clean fill without drips and a perfect seal every time. This reduces waste and cleaning needs. A custom machine also fits perfectly into your line, boosting overall productivity.

Customization is not just a luxury; for a serious food producer, it is a necessity. A standard machine forces you to adapt your product to the machine. A custom machine is built to serve your product perfectly.

Matching the Machine to Your Product

Yogurt comes in many forms. There is thin, drinkable yogurt, standard stirred yogurt, and very thick Greek-style yogurt. Each one flows differently. A custom machine will have the right kind of pump and filling nozzles for your specific product viscosity. This ensures a fast, clean fill without splashing or dripping. Drips and splashes on the machine create a mess that is hard to clean and becomes a breeding ground for bacteria. Getting the filling system1 right is key to maintaining a clean operation.

Perfect Fit for Your Packaging

Your cups are unique. They have a specific diameter, height, and shape. A custom machine2 is built with a mold that holds your cup securely. This means the cup is always perfectly aligned under the filler and the sealer. This guarantees an accurate fill level and, most importantly, a perfect heat seal. A weak or incomplete seal is one of the main ways that contaminants can get into the product after it leaves your factory. I visited a dairy in Morocco that was using a standard machine for an oddly shaped cup. Their rejection rate for bad seals was almost 10%. A custom machine from us with a perfectly matched sealing head fixed that problem completely, saving them a lot of money and protecting their brand.

Integrating into Your Production Line

A yogurt filler does not work alone. It needs to connect to your pasteurizer upstream and your conveyors and packing equipment downstream. A customized machine can be designed to fit perfectly into your existing layout. This creates a smooth, automated production line with minimal manual handling. The less the product is handled by people or exposed to the open environment, the safer it is. This seamless integration improves overall efficiency and hygiene at the same time.

Conclusion

Choosing the right yogurt filler is simple. Focus on hygiene features like a full enclosure, CIP cleaning, and UV sterilization. These guarantee product safety, quality, and a long shelf life.

-

Explore how Hygienic Machine Solutions enhance food safety and quality, ensuring customer satisfaction and brand trust. ↩ ↩

-

Explore this link to understand how CIP systems enhance cleaning efficiency and safety in food processing. ↩ ↩

-

Discover the importance of laminar flow hoods and UV sterilization in maintaining product safety and hygiene. ↩

Recent Posts

How Does Spout Bag Filling Machine Work?

Struggling with slow, messy manual filling? Worried about inconsistent product quality? An automated spout filling

How does a servo driving system improve a high-precision filling machine?

Are you losing money from inaccurate filling? This product waste hurts your brand and your

What is the Purpose of an Auto Pasteurizer in a Food Production Line?

Are your food products spoiling too quickly? This waste costs you money and limits how

How Do You Fill Mineral Water with Cup Filling Machine?

Struggling with high investment costs for bottling mineral water? There is a simpler, more affordable

How Do You Manufacture Ice Lolly Tubes From Start to Finish?

Struggling with slow, manual ice lolly production? Inconsistent quality and low output hurts your business.