Why Choose Our Ice Pop/Ice Lolly Filling and Sealing Machines

With over 15 years of specialized experience in manufacturing ice pop equipment, we deliver industry-leading solutions that combine efficiency, reliability and innovation to maximize your production capabilities.

Advanced Technology

Our machines incorporate the latest filling and sealing technologies, ensuring precise operation and consistent product quality with minimal waste.

Production Efficiency

Increase your production capacity with machines capable of producing up to 12,000 ice pops per hour, minimizing downtime and maximizing output.

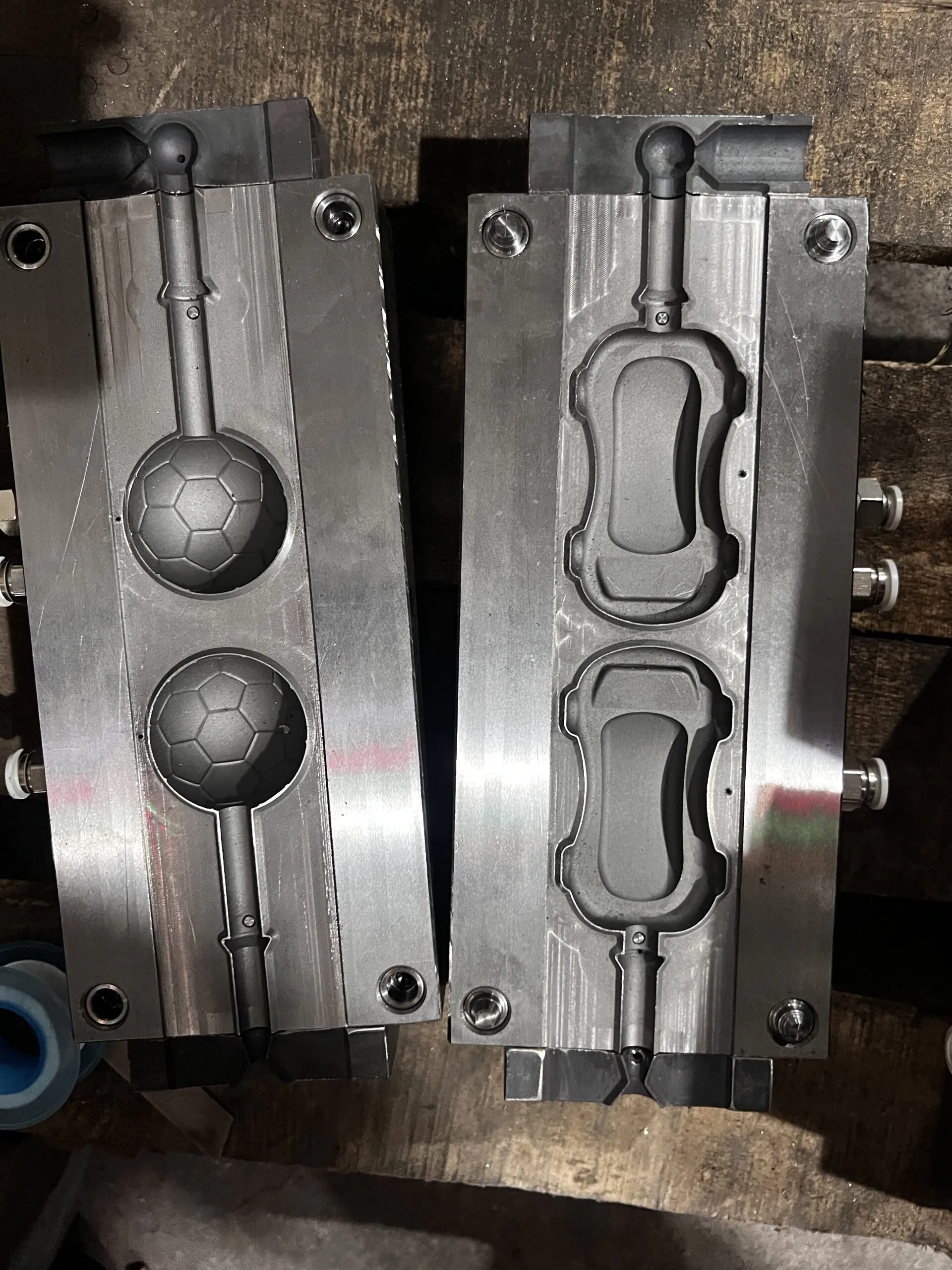

Customizable Solutions

We offer tailored machine configurations to meet your specific production requirements, accommodating various ice pop shapes, sizes, and flavors.

ISO 9001 Certified

Quality Guaranteed

15+

Years Experience

We Provide Complete Equipment for Your Ice Pop Business

Discover our comprehensive range of high-quality machines designed specifically for ice pop production, from molding to packaging.

Ice Pop Bottle Blow Molding Machine

High-precision blow molding equipment for creating perfect ice pop containers with customizable shapes and sizes.

Ice Lolly Filling and Sealing Machine

Fully automated system for precise filling and hermetic sealing of ice pops with adjustable volume control.

Ice Pop Packaging Machine

High-speed packaging solution with multi-lane operation for individual or group packaging of finished ice pop products.

Ice Pop Semi-auto Filling and Sealing Machine

Automated, power-saving precision filling at 6,000 pcs/hr. Adapts to any shapes, offering a smart, small investment for high efficiency.

Pasteurizer Tunnel

Our well-designed solution offers 1-4 ton/hr capacity, with insulated double walls and a long-life SS#304 conveyor for efficient, customizable output

Explore Best-Selling Products Made by Our Machines

Discover the diverse range of high-quality ice pops that can be produced with our state-of-the-art equipment, inspiring your next successful product line.

Strawberry Ice Pop

Natural fruit juice, smooth texture

Coca Ice Pop

Natural fruit juice, smooth texture

Twist Bottle

Rich chocolate with fudge swirls

Snake Ice Pop

Blend of strawberry, blueberry and raspberry

Ice pop

Blend of strawberry, blueberry and raspberry

Fruit Jelly

Jelly mixed with fruit flavour

Fruit Jelly

Jelly mixed with fruit flavour

Ice Pop

Blend of strawberry, blueberry and raspberry

"After implementing Xinchuang's ice pop production line, our output increased by 300% while maintaining perfect quality. Their machines are reliable and the customization options allowed us to create unique products that stand out in the market."

Alejandro

CEO, Sabor del Sol Inc.

Our engineers will help you design the perfect ice pop production line

Ice Pop Production Line Gallery

Explore detailed images of our high-precision ice pop production equipment

Explore our complete range of ice pop production equipment

Frequently Asked Questions

Get answers to the most common questions about our Ice Pop/Ice Lolly Filling and Sealing Machines.

Expert Technical Support

Our team of engineers provides round-the-clock assistance for all your production needs

Quick Response

24-hour technical support

Easy Maintenance

Simple to clean and service

Get in Touch

Have questions about our machinery solutions? Contact Guangdong Xinchuang Machinery Co.,LTD for customized food packaging equipment tailored to your specific needs.

Address

No.1 of No.1 Building, Boya Industrial Area, 283 Nanao Road, Jinping District, Shantou 515064, China

Phone

+86-754-88218350 | Mobile: +86-13715996256

Website

www.8xc.com