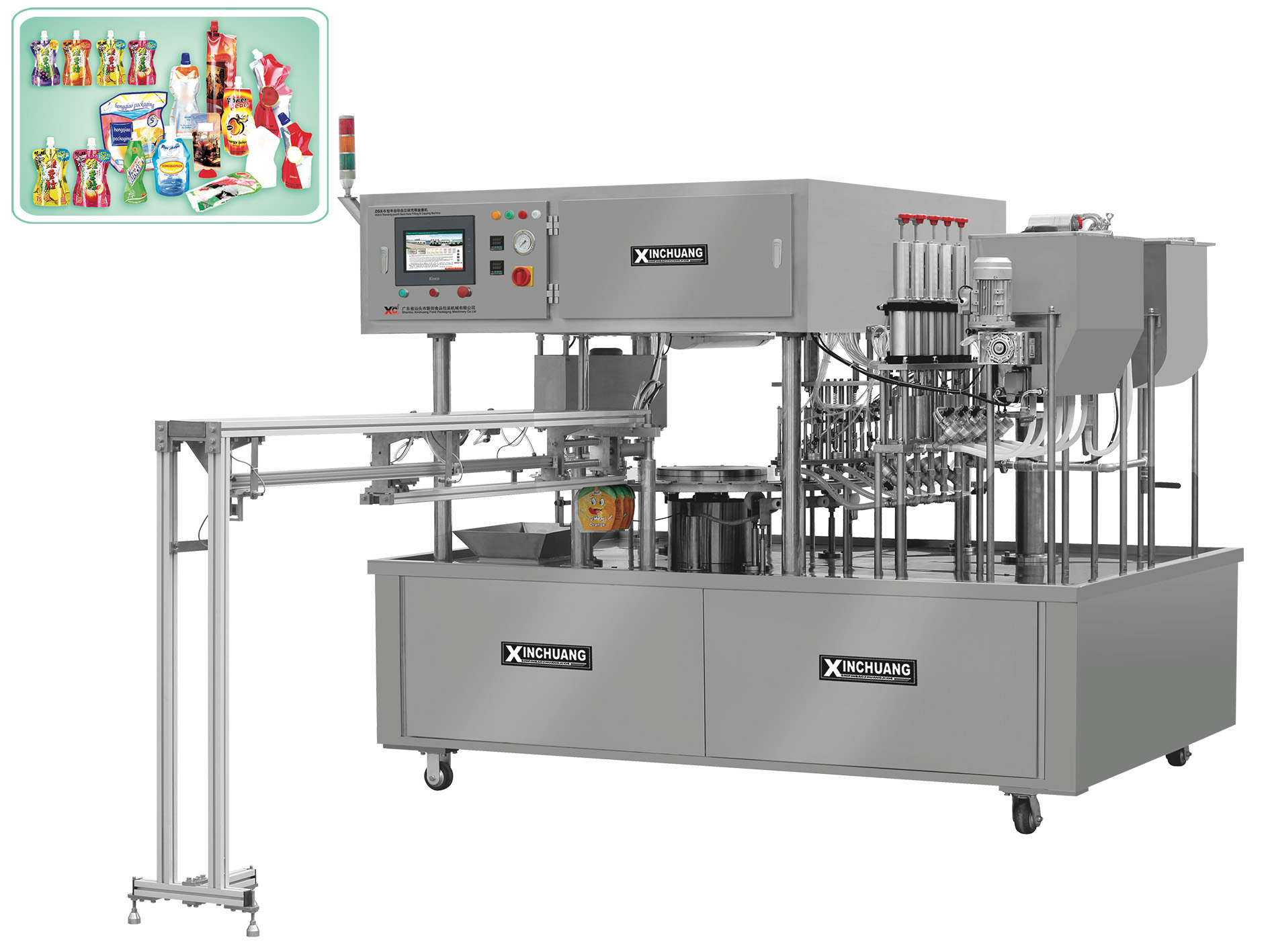

ZGX- Spout Pouch Auto Filling and Capping Machine

Your Trusted Source for Spout Pouch Auto Filling and Capping

ZGX-6 Auto Filling and Capping Machine

ZGX-5 Auto Filling and Sealing Machine

Tailored Solution For You

Endless product possibilities with our Filling and Capping Machine

Reliable Filling and Capping Machine Maufacture

The entire machine utilizes German-imported servo motors and pneumatic cylinders for stable and highly efficient control of every stage. Electrical components are from globally recognized brands such as Mitsubishi and Siemens. Includes a one-year free warranty

No matter the size or shape of your caps, our extensive customization capabilities can meet your exact requirements, ensuring stable and highly efficient production without manual intervention.

Our proprietary human-machine interface (HMI) and software support multiple languages, making the machine simple to operate

ervo-motor-driven capping provides precise torque control within a balanced range, ensuring consumers can easily open the product

With multi-track operation, our system automatically delivers spouted pouches to the filling process, maximizing throughput. Refer to the video below for a demonstration

Equipped with multiple imported machine tools and machining centers, we maximize machining precision and ensure complete control throughout the entire production process, providing you with superior service.