What Are the Different Types of Pouch Packaging Machines?

Struggling to find the right packaging solution? Overwhelmed by the variety of pouch packaging machines? You’re not alone.

Pouch packaging machines vary by design and function, including horizontal filling and sealing, filling and capping, vertical filling and sealing, and vacuum packing machines. Each type suits different packaging needs.

Choosing the right machine is essential. But first, let’s explore the different types and their uses.

How Many Types of Pouches Are There?

Confused about which pouch to choose? Wondering if there’s a perfect fit for your product? It’s a common dilemma.

There are many types of pouches, including stand-up, flat, spout, and retort pouches. Each offers unique benefits for different product types and uses.

Dive deeper into the world of pouches. Below is a table to help you understand:

| Pouch Type | Description | Common Uses |

|---|---|---|

| Stand-Up Pouches1 | Designed to stand upright on shelves. | Snacks, coffee, pet food. |

| Flat Pouches | Lay flat, ideal for single-serve items. | Condiments, powders, samples. |

| Spout Pouches | Feature a reclosable cap for easy pouring. | Liquids, baby food, detergents. |

| Retort Pouches2 | Withstand high temperatures for sterilization. | Ready-to-eat meals, soups, seafood. |

| Shaped Pouches | it has a special shape, according to the design. | Juice. |

| Zipper Pouches3 | there is a zipper at the end of the pouch | Dried fruit, nuts. |

| Three-side seal pouches | These are sealed on three sides, with one side left open for filling. | They are commonly used for snacks, powders. |

| Quad seal pouches | These pouches are sealed on all four corners, providing a stable base. | Coffee and pet food. |

Understanding these options is key. For example, I once helped a client switch from rigid containers to stand-up pouches. The change not only reduced shipping costs but also increased shelf appeal. Always consider what you want.

What Is a Pouch Packaging Machine?

Feeling lost in the world of packaging machinery? Is the idea of automating your packaging process daunting? We’ve all been there.

A pouch packaging machine automates filling and sealing products into pouches. It increases efficiency and consistency in packaging lines.

Let’s break down the main types:

Horizontal Filling and Sealing Machine

These machines handle pre-made pouches4. They are perfect for a range of products.

| Feature | Description | Benefit |

|---|---|---|

| Operation | Fills and seals pouches in a horizontal position. | Versatile for different pouch types. |

| Speed | Can handle high volumes. | Increases production efficiency5. |

| Products Handled | Suitable for solids, liquids, and powders. | Flexible for various industries. |

These are really popular for snacks.

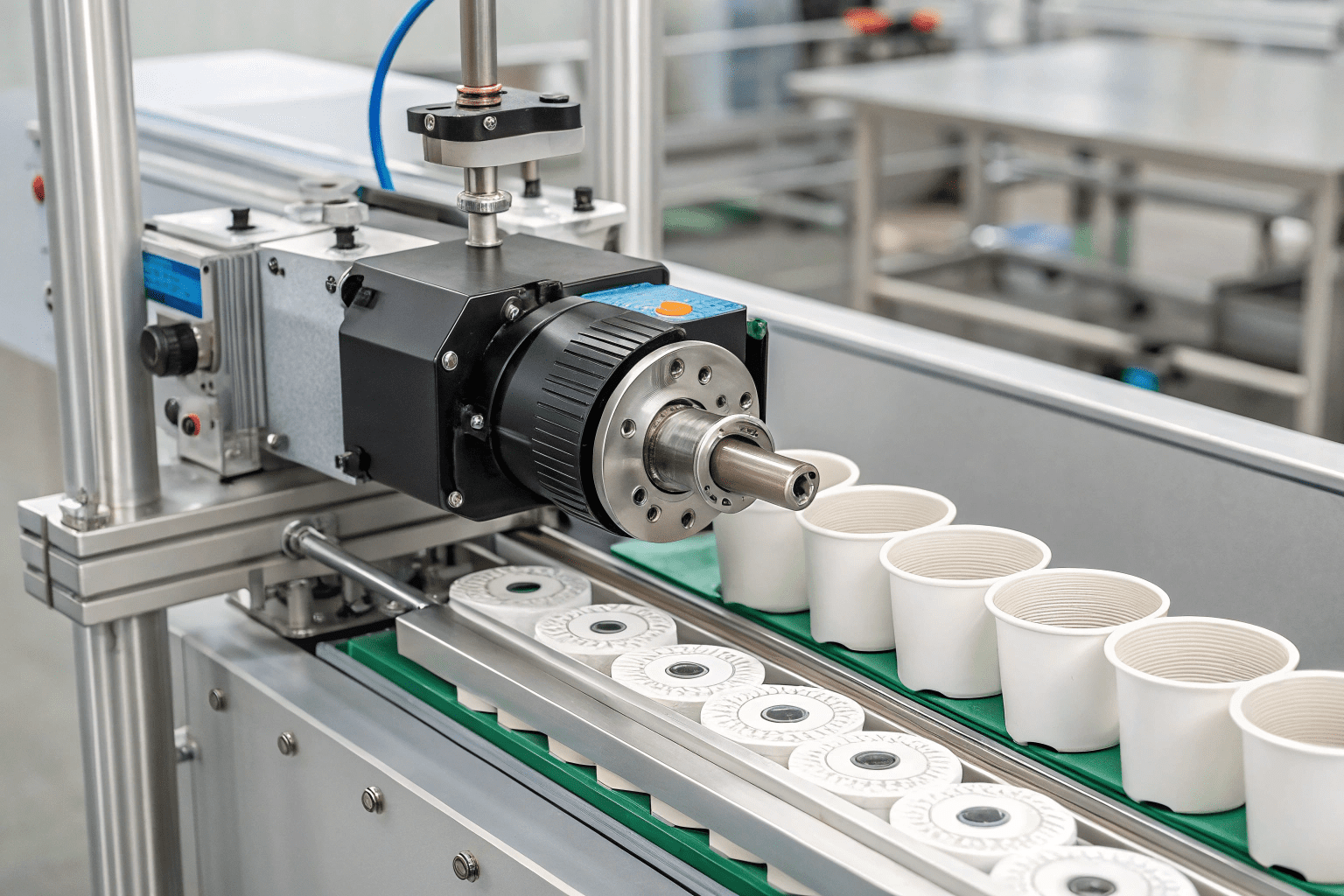

Filling and Capping Machine

Mostly for liquids and semi-liquids6. This is a common choice.

| Feature | Description | Benefit |

|---|---|---|

| Operation | Fills pouches, then adds and secures a cap. | Ensures product freshness and ease of use. |

| Speed | Varies, but generally efficient for medium to high production. | Streamlines the filling and capping process7. |

| Uses | Ideal for beverages, sauces, and cleaning products. | Provides a secure, user-friendly package8. |

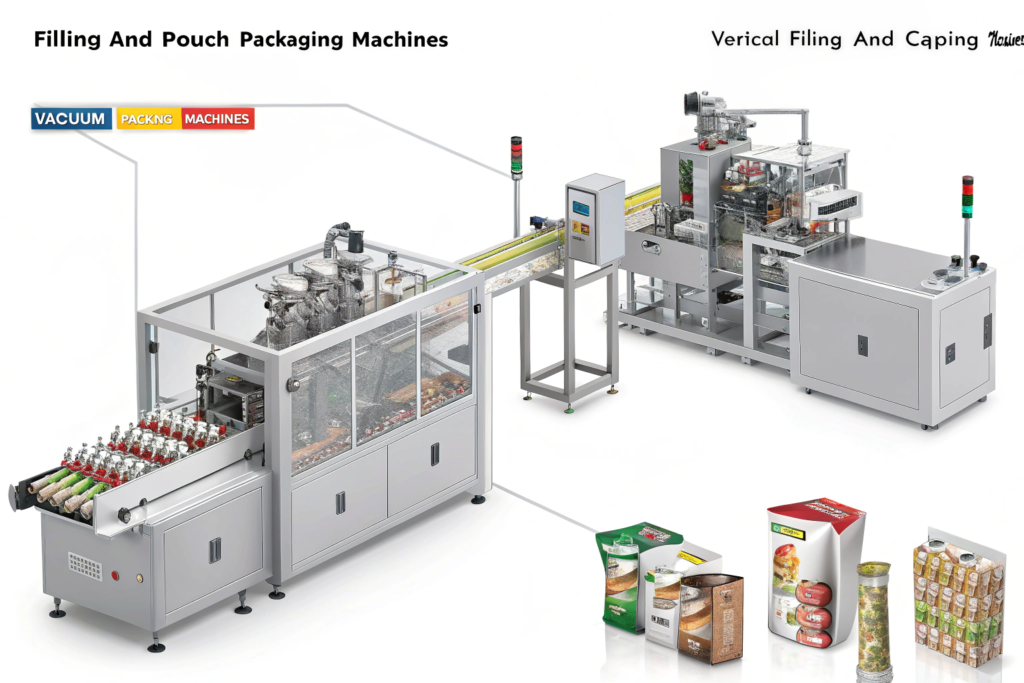

Vertical Filling and Sealing Machine

These machines form, fill, and seal pouches.

| Feature | Description | Benefit |

|---|---|---|

| Operation | Uses roll stock film to create, fill, and seal pouches in a vertical motion. | Cost-effective for large production runs. |

| Speed | High-speed capabilities. | Maximizes output. |

| Products Handled | Best for free-flowing products like powders and granules. | Offers a compact and efficient solution. |

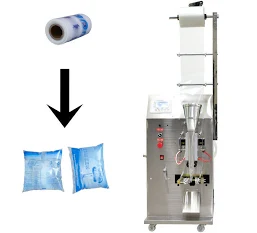

Vacuum Packing Machine

These machines make sure products stay fresh for a long time.

| Feature | Description | Benefit |

|---|---|---|

| Operation | Removes air from the pouch before sealing. | Extends shelf life by preventing oxidation. |

| Speed | Slower than other types due to the vacuum process. | Essential for preserving perishable goods9. |

| Products | meats, cheese, and other perishable foods. | Maintains product quality and reduces waste. |

Choosing the right machine depends on your product. Think about its shape, volume, and how long it needs to stay fresh.

Conclusion

Picking the right pouch packaging machine can be hard. Understanding the types of machines and pouches makes it simpler.

-

Explore the advantages of Stand-Up Pouches, including cost savings and enhanced shelf appeal, to make informed packaging decisions. ↩

-

Learn how Retort Pouches maintain food safety through sterilization, making them ideal for ready-to-eat meals. ↩

-

Discover the convenience and freshness benefits of Zipper Pouches, perfect for storing snacks and dried goods. ↩

-

Exploring this resource will provide insights into the advantages and applications of pre-made pouches in various industries. ↩

-

This link will offer strategies and tips to enhance production efficiency, crucial for any manufacturing business. ↩

-

Explore innovative packaging solutions tailored for liquids and semi-liquids to enhance product quality and user experience. ↩

-

Understanding the filling and capping process can help improve efficiency and product integrity in packaging operations. ↩

-

Discover the key features that contribute to a user-friendly package, enhancing customer satisfaction and product accessibility. ↩

-

Discover various techniques for preserving perishable items, including vacuum packing, to minimize waste and maintain quality. ↩