What Are the Safety Features of a Cup Filling and Sealing Machine?

Facing problems with your packaging line? Worried about potential hazards and downtime? It’s a common concern in fast-paced production.

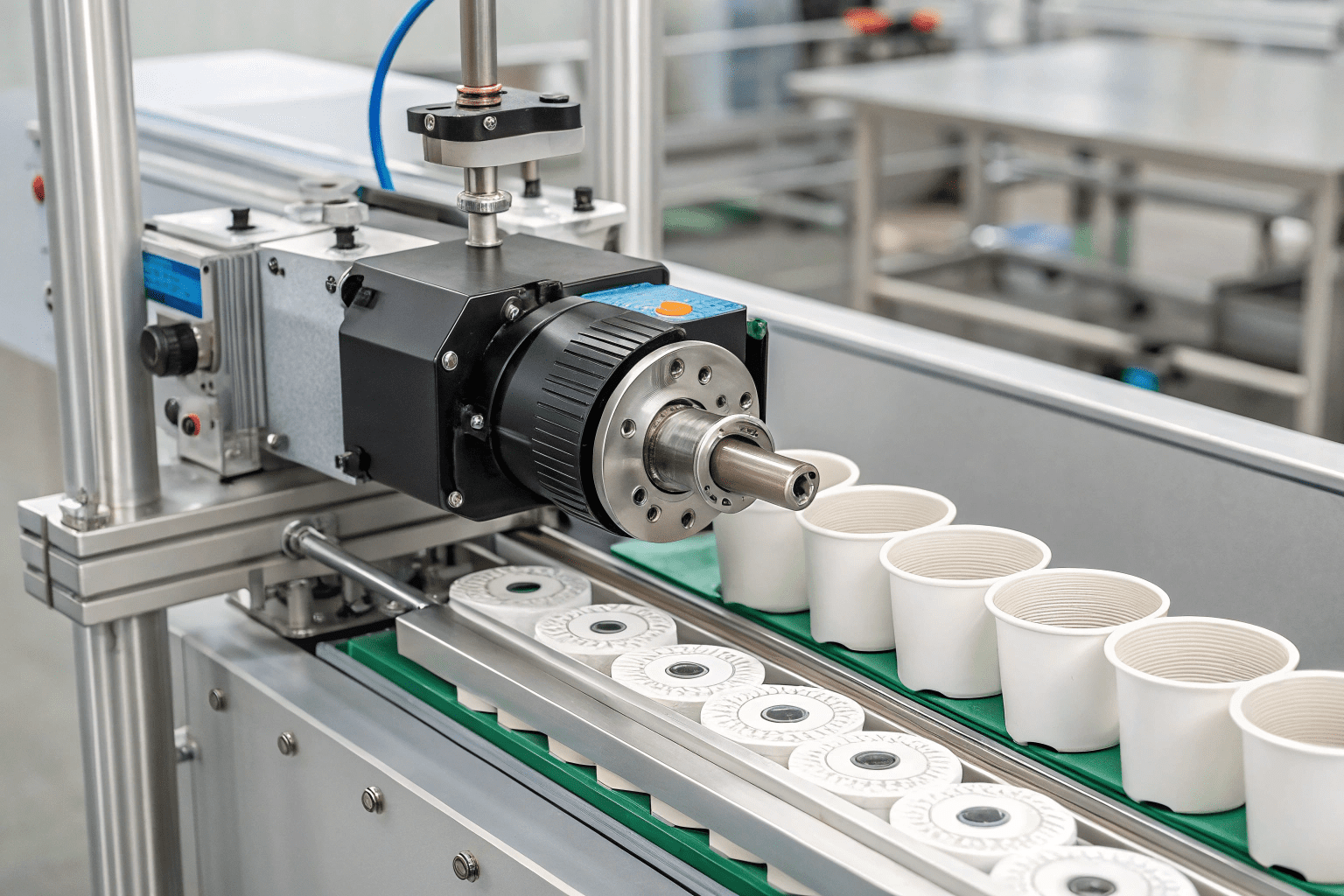

Cup filling and sealing machines have several key safety features: no cup-no fill-no seal, film misalignment detection, auto-level control, interlock guards, and emergency stop buttons. These protect operators and prevent material waste.

Safety is paramount in any industrial setting, especially when dealing with automated machinery. So I have described some safety feartures for you. Let’s explore.

What is the Working Principle of a Sealing Machine?

Feeling frustrated by inconsistent seals and product leakage? Inconsistent sealing is a significant issue, leading to waste and customer dissatisfaction.

Sealing machines typically use heat and pressure to melt a plastic film onto a container. A heated element presses the film, creating a hermetic seal. Precise temperature and pressure control ensure consistent results.

Let’s take a closer look at the safety and working. I will explain below for a better understanding.

Safety Features Explained

These machines, while efficient, come with inherent risks if not designed and operated correctly. These are some key safety features of cup filling machines.

| Feature | Description | Benefit |

|---|---|---|

| No Cup-No Fill-No Seal1 | Sensors detect the presence of a cup. If no cup is detected, the filling and sealing functions are automatically disabled. | Prevents spillage, waste of filling material, and mess. |

| Film Misalignment2 | Optical sensors monitor the position of the sealing film. If the film is misaligned, the machine stops, and an alert may be triggered. | Prevents faulty seals, ensures proper packaging, reduces product loss. |

| Auto Level Control | Sensors maintain the correct level of filling material in the hopper or tank. | Prevents overfilling or underfilling, ensures consistent product volume. |

| Interlock Guards | Physical barriers or guards are in place around moving parts. These guards are interlocked with the machine’s control system. | Prevents accidental contact with moving parts, reducing injury risk. |

| Emergency Stop Button3 | A prominent, easily accessible button that, when pressed, immediately shuts down all machine operations. | Allows for immediate shutdown in case of an emergency. |

Sealing Machine: Working Principle

The simple operation can make you understand the function. Sealing is at the heart of protecting your product and ensuring its quality.

- Heating Element4: The core of most sealing machines is a heating element, often a metal bar or wire. This element reaches a precise temperature.

- Pressure Application5: Once the film is in place, a mechanism, applies pressure. This pressure, combined with the heat.

- Cooling and Release: After the dwell time, the heating element may retract or cool down. Then releasing the sealed container.

- Types of Sealing6:

- Heat Sealing: Most common for thermoplastics.

- Impulse Sealing: A brief burst of heat.

- Continuous Band Sealing: For high-speed.

| Sealing Method | Description | Common Applications |

|---|---|---|

| Heat Sealing | Uses a heated element to melt thermoplastic film. | Food packaging, medical devices, general packaging. |

| Impulse Sealing | Applies a short burst of heat followed by cooling under pressure. | Thicker materials, bags requiring a strong seal. |

| Band Sealing | Two heated, rotating belts carry the material. | High-speed. |

Conclusion

Cup filling and sealing machines are designed with built-in safety precautions. No-cup, no-fill helps prevent spills, while interlock guards protect operators. Understanding the principles helps to optimize the sealing process.

-

Explore how this technology prevents waste and mess in packaging processes. ↩

-

Learn about the importance of film alignment in ensuring product integrity and reducing losses. ↩

-

Understand the significance of emergency stop buttons in enhancing safety in industrial operations. ↩

-

Understanding the heating element’s function is crucial for optimizing sealing processes and ensuring product quality. ↩

-

Exploring pressure application can enhance your knowledge of effective sealing techniques and improve packaging efficiency. ↩

-

Learning about various sealing types can help you choose the best method for your specific packaging needs. ↩