What is a cup filling machine used for?

Your manual packaging is slow and messy, right? This costs you money and makes your product look unprofessional. A cup filling machine solves this by automating the whole process.

A cup filling machine is used to automatically put products like liquids, pastes, or granules into cups. It then seals the cups, making them ready for sale. It’s essential for mass-producing items like yogurt, juice, jelly, and sauces.

I see a lot of new clients who know they need a machine, but they get confused by all the options. It’s a big investment, so understanding the different types is your first important step. Let me break it down for you so you can make a smart choice for your business.

What are the different types of cup filling machines?

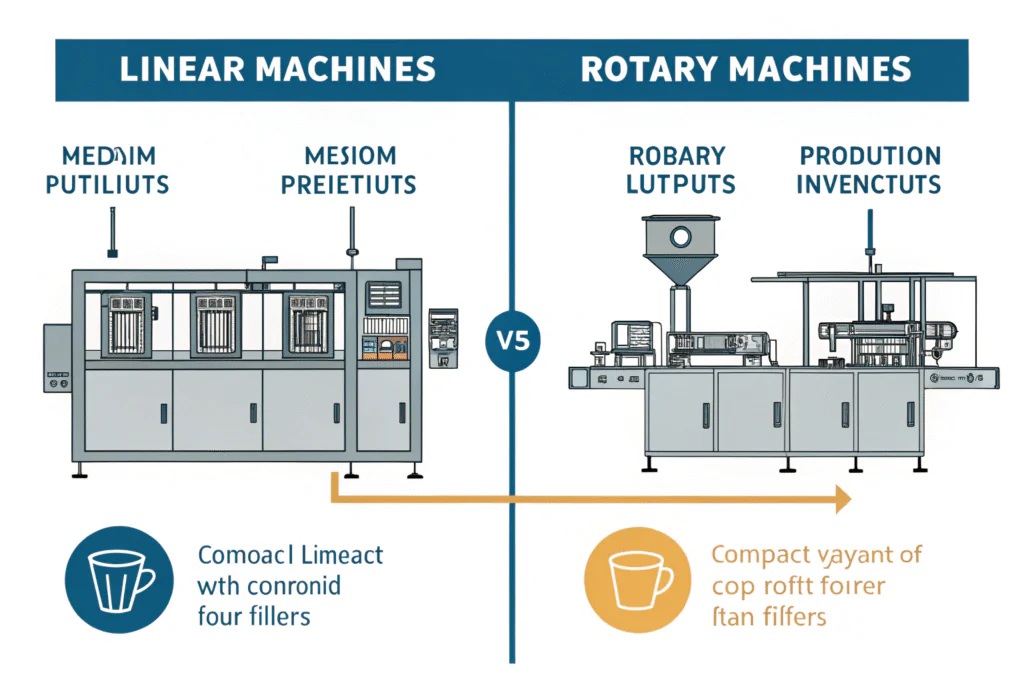

Choosing a machine feels overwhelming, doesn’t it? The wrong choice can waste your money and factory space. Let’s look at the two main types to find your perfect fit.

The two main types are linear and rotary. Linear machines are for high-volume production and are often more compact in width. Rotary machines are great for smaller to medium outputs and are usually a lower initial investment.

When a client comes to me, the first question I ask is about their production goals. This helps us decide between a linear or a rotary machine. They are both great, but they serve different needs. Think of it like choosing between a delivery van and a large truck. Both carry goods, but you choose based on the size of your operation. One of my clients in the Philippines started with a small rotary machine for his yogurt business. As his sales grew, he came back to us two years later for a high-speed linear machine. This is a very common path for growing businesses.

The High-Speed Linear Machine

A linear machine works just like its name sounds. The cups move in a straight line through each station: dropping, filling, sealing, and cutting. Because it’s a straight path, we can add more lanes to increase output. A 4-lane machine produces twice as much as a 2-lane machine. These are workhorses, built for speed and high volume. They are perfect for big factories that need to produce tens of thousands of cups per hour. They also fit well into long, narrow factory spaces. The main thing to know is that they require a bigger initial investment.

The Versatile Rotary Machine

A rotary machine has a large, circular plate that turns. The cups are placed on this plate and rotate from one station to the next. It’s a very compact design that often takes up a more square-shaped floor space. These machines are the most popular choice for startups and small-to-medium-sized businesses. The investment is lower than a linear machine, making it a safer first step into automation. While they are not as fast as the biggest linear machines, they can still produce thousands of cups an hour, which is perfect for a business that is just starting to supply local supermarkets.

| Feature | Linear Machine | Rotary Machine1 |

|---|---|---|

| Production Speed | Very High (e.g., 8,000-70,000 cups/hr) | Medium to High (e.g., 2,000-10,000 cups/hr) |

| Footprint | Narrow and Long | Wider, more square-shaped |

| Initial Cost | Higher | Lower |

| Best For | Large-scale, established production | Startups, medium-scale production |

What is the process of a cup filling machine?

The idea of a fully automated machine can be intimidating. You worry about what happens inside. But the process is actually a series of simple, logical steps that anyone can understand.

The machine’s process is straightforward. It automatically drops a cup, fills it with your product, puts a sealing film on top, prints a date, heat-seals the film, and then cuts the film.

Understanding this process is important. It helps you see how simple automation can be. When you know each step, you can better manage production and troubleshoot any small issues. It removes the mystery and gives you confidence in your investment. I always walk my clients through each step using videos of their actual machine before we ship it. It makes them feel much more comfortable. The machine might look complex from the outside, but it’s just doing a few simple jobs, one after another, very quickly. Let’s look at each step in detail.

Step 1: Cup Dropping and Filling

First, you load a stack of empty cups into the machine’s dispenser. The machine then uses a mechanism to separate one cup at a time and drop it perfectly into a custom-made mold. This mold holds the cup securely as it moves to the next station. Once the cup is in place, the filling nozzle comes down. It dispenses the exact amount of your product. We customize this for whatever you are making, whether it’s a liquid like juice, a paste like yogurt, or granules like small candies. This step ensures every single cup has the same amount of product, which is key for quality control and cost management.

Step 2: Film Placement and Sealing

After the cup is filled, it moves to the sealing station. A roll of pre-printed sealing film is positioned over the top of the cup. Just before the film is sealed, a date coder prints the production date or expiration date onto the film. This is a very important step for food safety. Then, a heated sealing head presses down firmly. The heat and pressure melt a thin layer on the film, bonding it tightly to the rim of the cup. This creates an airtight seal that keeps the product fresh and prevents any leaks. The temperature and pressure are carefully controlled to create a perfect seal every time.

Step 3: Cutting and Ejection

This is the final step that makes the product look professional. The cup, now sealed with a square of film, moves to the cutting station. Here, a cutting die that is the exact shape of the cup’s rim presses down. It cleanly cuts away the extra film around the edges, leaving a perfect, neat seal. The finished product now looks just like the ones you see in the supermarket. Finally, the cup is automatically pushed out of the machine. It usually lands on an exit conveyor belt, ready to be packed into boxes. This whole cycle, from empty cup to finished product, happens in just a few seconds.

Conclusion

In short, a cup filling machine automates your packaging from start to finish. Understanding the types and process helps you choose the right machine to grow your food business.

-

Explore the advantages of Rotary Machines for efficient production, especially for startups and small businesses. ↩

Recent Posts

What is the Purpose of an Auto Pasteurizer in a Food Production Line?

Are your food products spoiling too quickly? This waste costs you money and limits how

How Do You Fill Mineral Water with Cup Filling Machine?

Struggling with high investment costs for bottling mineral water? There is a simpler, more affordable

How Do You Manufacture Ice Lolly Tubes From Start to Finish?

Struggling with slow, manual ice lolly production? Inconsistent quality and low output hurts your business.

Ice Cup Filling Machine, How to Produce Ice Cup?

Confused about making ice cups efficiently? The process might seem complicated, involving multiple machines and

How to Produce Butterfly Jelly with Our Filling Machine?

How to Produce Butterfly Jelly with Our Filling Machine? Struggling to create eye-catching, multi-colored jellies?