Losing time and product with messy, slow manual filling? This inefficiency costs your business money and hurts your brand’s reputation, stopping you from meeting growing customer demand.

A K-cup filling and sealing machine is a fully automatic device. It takes empty capsules, fills them with powders like coffee or milk, and then securely heat-seals a lid on top. This creates a finished, market-ready product with high efficiency and precision.

So you know the basics of what this machine does. But how does it transform an empty plastic cup into a perfectly sealed coffee pod ready for your customers? The process is a smooth flow of mechanical precision1. It is fascinating to see how each step seamlessly connects to the next. Let’s dig into the details to see exactly how this technology can revolutionize your production line2.

How does the K-cup filling process actually work?

Understanding the inner workings of a production machine can feel complicated. This lack of clarity can make you hesitate, possibly leading to a poor investment that doesn’t fit your needs.

The process is simple. The machine first drops an empty cup into place. An auger filler then measures and pours the correct amount of powder. The powder is pressed down, a foil lid is placed on top, and it is heat-sealed before being ejected.

Let’s break down the journey of a single K-cup inside the machine. It is a sequence of precise actions, each one critical for the final product’s quality. I remember showing a new client from Indonesia this process. He was amazed at how every step was perfectly synchronized to prevent waste and ensure quality.

From Empty Cup to Sealed Product

The machine’s workflow is typically set up on a rotary table or a linear conveyor. Everything starts with the cups.

-

Cup Dispensing: The machine automatically singles out an empty cup from a stack and drops it perfectly into a holder on the production line2. This step must be reliable to keep the entire line moving without interruption.

-

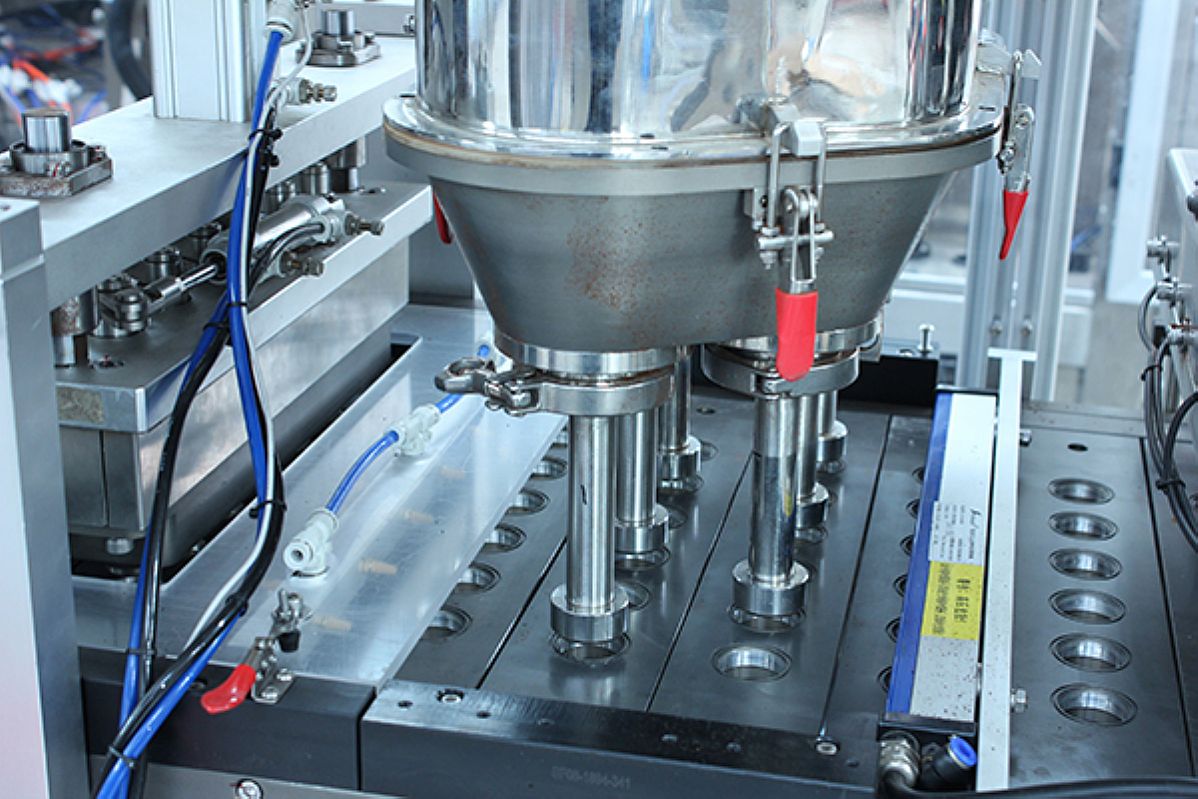

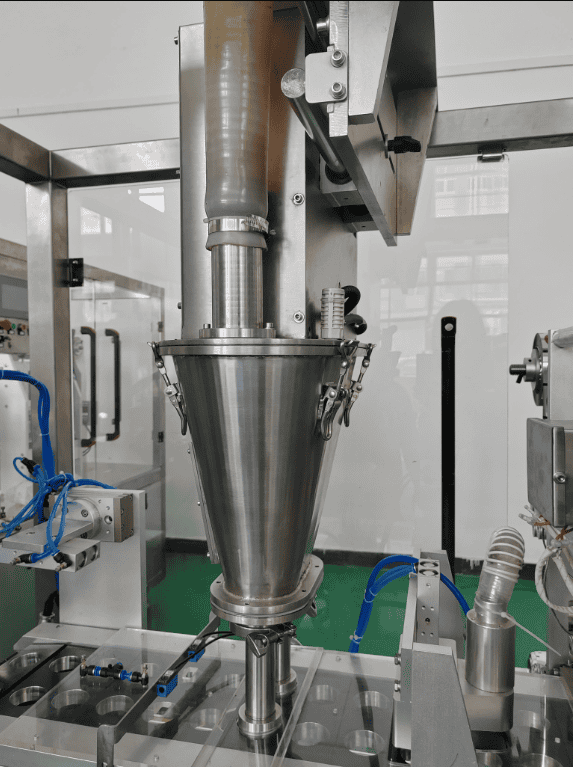

Powder Filling: This is the most critical step. The machine uses an auger filler, which is basically a large screw. As the screw turns, it dispenses a very precise amount of coffee powder into the cup below. This method is fantastic for powders because it guarantees each cup has the exact same weight.

-

Tamping and Cleaning: After filling, a small press comes down and tamps the powder. This compacts it for a better brew and ensures there’s space for the seal. A small vacuum or blower then cleans any loose powder from the rim of the cup, which is vital for a strong seal.

-

Lid Placement and Sealing: The machine then places a pre-cut foil lid on top. Immediately after, a heated sealing head presses down, using heat and pressure to melt the lid onto the cup’s rim. This creates an airtight seal3 that locks in freshness.

-

Ejection: Finally, a mechanical arm or a puff of air ejects the finished K-cup from the line onto a conveyor belt for packaging.

Here is a simplified table of the process:

| Step | Action | Purpose |

|---|---|---|

| 1. Cup Dropping | Places an empty K-cup into position. | Starts the automated process. |

| 2. Auger Filling | Dispenses a precise amount of powder. | Ensures consistent product weight and quality. |

| 3. Tamping | Compacts the powder in the cup. | Creates an even bed for better brewing. |

| 4. Lid Placing | Places a pre-cut foil lid on the cup. | Prepares the cup for a perfect seal. |

| 5. Heat Sealing | Applies heat and pressure to seal the lid. | Creates an airtight seal3 to preserve freshness. |

| 6. Cup Ejection | Removes the finished K-cup from the line. | Completes the cycle for the next cup. |

This entire cycle happens in just a few seconds, allowing for the production of thousands of cups per hour.

Why is an automated machine better than manual filling?

You might think that using manual labor is a cheaper way to start. But this approach often leads to inconsistent products, high labor costs4, and slow production, which limits your ability to grow your business effectively.

An automated machine is superior due to its incredible speed, precision, and hygiene. It drastically cuts labor costs, minimizes product waste5, and ensures every K-cup is identical and perfectly sealed. This guarantees consistent quality and boosts your production capacity enormously.

When I talk to potential customers at events like the Canton Fair, this is a topic that always comes up. A factory owner from Morocco once told me his biggest headache was customer complaints. Some coffee pods were too strong, and others were too weak. His manual process was creating an inconsistent product. After investing in one of our machines from Guangdong Xinchuang Machinery industry Co.,Ltd, his quality problems disappeared. He came back the next year to buy a second machine. The difference between manual and automated processes is night and day, especially when you look at the numbers.

Speed, Quality, and Cost

The decision to automate goes beyond just speed; it impacts your entire business operation from quality control to your bottom line.

-

Massive Speed and Output: A single worker might fill a few hundred cups an hour, with breaks and inconsistencies. Our standard K-cup machine can easily produce 3,000 to 6,000 cups per hour, running steadily all day. A client in Vietnam saw their output increase by more than 500% overnight.

-

Unmatched Consistency: A human can’t pour the exact same 10.5 grams of coffee a thousand times in a row. An auger filler can. This means every single cup you sell will provide the same experience for the customer. The sealing process is also perfectly controlled for temperature and pressure, eliminating leaks and preserving freshness, which is a feature of our stable machines.

-

Superior Hygiene: Manual filling exposes the product to the open air and human contact, increasing the risk of contamination. An automated machine is a closed system. The product moves from the hopper to the sealed cup with minimal exposure, which is critical for food safety standards in markets like Saudi Arabia and across Europe.

Here’s a direct comparison:

| Feature | Manual Filling | Automated Machine |

|---|---|---|

| Speed | Slow, about 200-500 units/hour per person. | Very fast, 3,000+ units/hour. |

| Consistency | Low, fill weight can vary by +/- 10%. | High, fill weight is precise to +/- 1-2%. |

| Labor Cost | High and continuous. You pay for every hour. | Low. A single operator can manage the machine. |

| Product Waste | Higher due to spills and incorrect fills. | Minimal, saving you money on raw materials. |

| Long-Term ROI | Low. Costs increase as you hire more people. | High. The machine pays for itself over its long service life. |

The initial investment in a machine is just that—an investment. It is a capital expense that quickly pays for itself by reducing your operational costs and allowing your business to scale in ways manual labor never could.

What other products can this machine fill?

Thinking a K-cup machine is only for coffee can limit your creative business ideas. This belief could be stopping you from tapping into profitable markets for instant tea, hot cocoa, or powdered milk, causing you to miss major opportunities.

Beyond coffee, this machine expertly handles a wide range of powders. This includes milk powder, cocoa, instant tea mixes, and even nutritional supplements. Its versatility comes from the precise auger filling system, which can be adapted for different product densities and flow properties.

I often see a look of surprise on people’s faces when I explain this. At a trade show in Russia, a potential customer was focused only on coffee for his local market. I showed him a video of our machine running in an Algerian factory, filling capsules with instant powdered milk for children’s drinks. His whole perspective changed. He saw two new product lines he could launch immediately with the same machine. This adaptability is a core strength of our equipment at Xinchuang Machinery.

Expanding Your Product Line

The auger filling mechanism is the key to this machine’s versatility. By adjusting the auger’s size, rotation speed, and other settings, we can customize it for a variety of powders.

-

Dairy and Drink Mixes6: The machine is perfect for milk powder, coffee creamer, and hot chocolate mixes. These products are very popular in markets across the Middle East and South Asia. We have customers in Pakistan and Bangladesh using our machines to create affordable, single-serve milk drinks. The key is managing the powder’s fat content and flowability, which we can tune the machine for.

-

Teas and Herbal Infusions7: Instant tea powder is a huge market, especially in countries like India, Iran, and in many parts of Africa. Our machines can fill capsules with black tea powder, green tea mixes, or even powdered herbal infusions. This allows companies to offer a convenient alternative to tea bags.

-

Customizable for Your Needs: Not all powders behave the same. Some are light and fluffy, some are dense, and others can be sticky. At my company, we work directly with clients to understand their specific product. We can modify the machine to handle their unique powder, ensuring smooth, efficient, and accurate filling every time. This customization is a key part of our promise of top quality.

Here are a few examples of what our machines can handle:

| Product Category | Specific Examples | Key Filling Consideration |

|---|---|---|

| Coffee | Ground Espresso, Drip Coffee, Flavored Coffee | Particle size, density, oil content. |

| Dairy Powders | Whole Milk Powder, Non-Fat Creamer | Flowability, fat content, potential for static. |

| Beverage Mixes | Hot Cocoa, Instant Tea, Fruit Drink Powder | Sugar content, mix uniformity, avoiding clumps. |

| Supplements | Protein Powder, Powdered Vitamins | Precise dosage accuracy, strict hygiene. |

So, when you invest in a K-cup filling and sealing machine8, you are not just buying a coffee packer. You are buying a versatile platform that can help your business grow and diversify its product offerings for years to come.

Conclusion

A K-cup filling machine automates production, boosts quality, handles diverse powders, and is a smart investment. It allows your business to scale efficiently and meet modern market demands.

-

Understand the importance of mechanical precision in production lines. ↩

-

Understand the concept of production lines in manufacturing. ↩ ↩

-

Discover why airtight seals are crucial for product preservation. ↩ ↩

-

Understand how automation can lead to significant cost savings. ↩

-

Explore the factors contributing to product waste in manual filling. ↩

-

Explore how K-cup machines can efficiently fill dairy and drink mixes. ↩

-

Discover the potential of K-cup machines in the tea market. ↩

-

Explore this link to understand how K-cup machines can enhance your production efficiency. ↩