What is Clean-In-Place (CIP) and How Does It Keep Your Filling Machine Safe?

Worried about product contamination ruining your production run? Cleaning complex machinery takes time and effort. CIP offers an automated solution to keep things sanitary without disassembly.

Clean-In-Place (CIP) is an automated method for cleaning the interior surfaces of pipes, vessels, and process equipment, like filling hoppers, without taking them apart. It ensures critical components in your cup filling and sealing machine remain free from contaminants, especially vital for dairy products.

Understanding how this cleaning magic happens is key to appreciating its value. Let’s break down the process and why it’s become standard practice, particularly when handling sensitive products like yogurt or milk where hygiene is absolutely critical. We need to look closer at the steps involved.

What Are the Typical Steps in a CIP Process?

Keeping your production line clean feels like a constant battle, right? Manual cleaning risks errors and inconsistencies. A structured, automated CIP process removes the guesswork and ensures thorough sanitization every time.

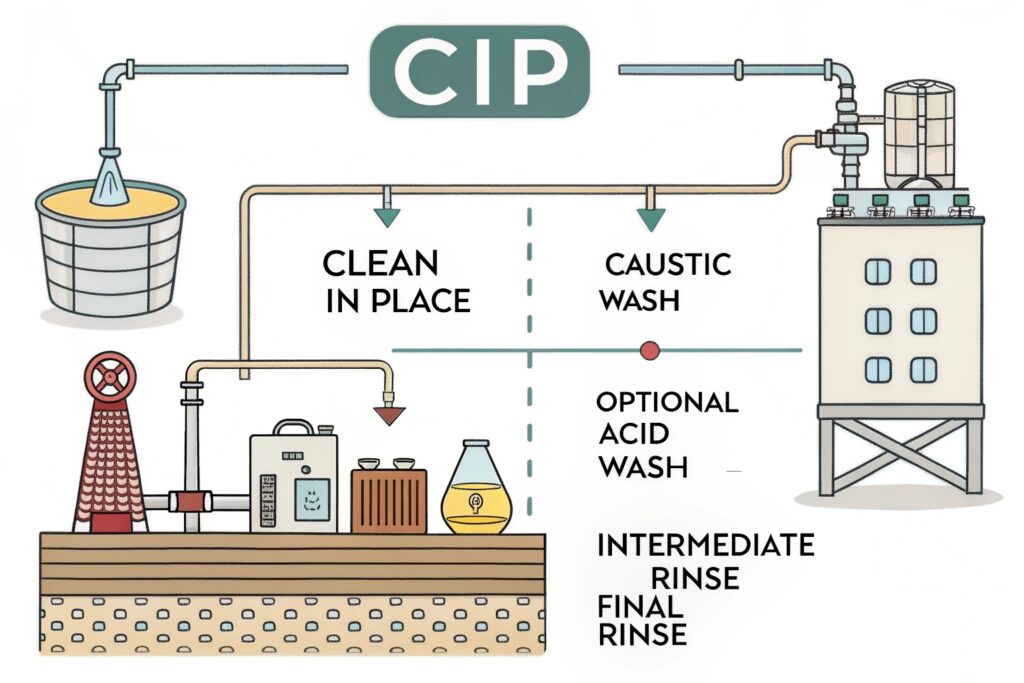

The core CIP process usually involves these key stages: a pre-rinse, a caustic wash, an intermediate rinse, an acid wash (optional but common), and a final rinse. This sequence effectively removes soils and sanitizes equipment surfaces.

Let’s explore what happens during each of these stages. From my experience in the factory, seeing this automated process run smoothly is impressive, especially knowing how much manual effort it saves. Each step has a specific job to do to ensure the filling machine, especially parts like the hopper and filling nozzles, are completely clean and ready for the next batch.

Breaking Down the CIP Cycle

The effectiveness of CIP comes from its methodical approach. Here’s a typical breakdown:

-

Pre-Rinse:

- What: The cycle starts with flushing the system, usually with recovered water or fresh cold/hot water.

- Why: This initial step removes loose debris, leftover product (like milk residue or yogurt), and gross soils. Think of it like rinsing your plate before washing. It makes the later cleaning steps much more effective and saves on detergent.

-

- What: Hot water mixed with a caustic detergent (like sodium hydroxide) circulates through the equipment.

- Why: This is the main cleaning step. The high pH solution breaks down and saponifies fats, proteins, and other organic residues commonly found in food products. The heat helps speed up the chemical reactions.

-

Intermediate Rinse:

- What: Flushing the system with fresh water.

- Why: This rinse removes the loosened soil and residual caustic detergent solution, preventing it from reacting with the acid in the next step (if used) and ensuring the acid wash works effectively.

-

- What: An acid solution (like nitric or phosphoric acid) circulates through the system. This step isn’t always necessary, depending on the product and water hardness.

- Why: The acid wash dissolves mineral scale (like milkstone from dairy products) and protein residues that the caustic wash might not fully remove. It also helps neutralize any remaining alkaline residue.

-

- What: A thorough flush with clean, potable water (sometimes sterilized or WFI – Water For Injection – in pharma).

- Why: This crucial step removes all traces of cleaning agents, ensuring the equipment is clean, sanitized (if a sanitizing agent is added here or as a separate step), and ready for production without risk of chemical contamination.

| Step | Purpose | Typical Agent | Key Benefit |

|---|---|---|---|

| 1. Pre-Rinse | Remove loose soil, gross product residue | Water | Improves detergent efficiency |

| 2. Caustic Wash | Dissolve fats, proteins, organic matter | Alkali Detergent | Primary cleaning step |

| 3. Intermediate Rinse | Remove detergent & loosened soil | Water | Prepares for next step |

| 4. Acid Wash | Dissolve mineral scale, protein films | Acid Solution | Removes stubborn inorganic soils |

| 5. Final Rinse | Remove all cleaning agents, final sanitation | Potable Water | Ensures product safety |

This systematic approach ensures a repeatable and verifiable clean, which is essential for meeting hygiene standards.

Why is a CIP System Essential for Your Filling Machine?

Running a food production line without reliable cleaning is risky. Contamination scares, product recalls, and damage to your brand reputation are serious concerns. Relying solely on manual cleaning introduces variability and potential errors.

A CIP system is an integrated setup of tanks, pumps, valves, and controls designed to automate the entire cleaning process described above. It’s essential because it delivers consistent, verifiable cleaning results, improves safety, reduces downtime, and ensures compliance.

Think about the parts of your filling and sealing machine – the hopper holding the yogurt, the pipes transporting the juice, the nozzles filling the cups. These need to be spotless. A dedicated CIP system isn’t just a nice-to-have; I see it as a fundamental part of ensuring safe and efficient production, especially for clients dealing with dairy or other sensitive food items.

Components and Advantages of a CIP System

A typical CIP system isn’t just about the cleaning cycle; it’s the hardware and software working together. Key components often include:

- Tanks: To hold water (fresh and recovered), detergent solutions (caustic and acid), and sometimes rinse water.

- Pumps: Powerful pumps circulate the cleaning solutions through the equipment circuit at the required flow rate and pressure.

- Valves and Piping: Automated valves direct the flow of different solutions and water through the correct paths in the filling machine and back to the CIP skid. This includes routing to the main hopper, filling pistons, and nozzles.

- Heating System4: Often uses heat exchangers (steam or electric) to bring cleaning solutions to the optimal temperature for effectiveness.

- Instrumentation5: Sensors monitor temperature, flow rate, pressure, and solution concentration (conductivity) to ensure the cleaning parameters are met.

- Control System (PLC)6: The brain of the operation. It manages the sequence, timing, valve operations, and monitors all parameters, providing data logging for verification.

Why invest in this? The advantages are significant:

- Consistency: Removes human error, ensuring every clean meets the same validated standard.

- Safety: Reduces employee exposure to harsh cleaning chemicals.

- Efficiency: Faster cleaning cycles compared to manual methods mean less downtime and more production time.

- Resource Savings: Optimizes water and chemical usage compared to manual cleaning. Recirculation and recovery systems can further enhance this.

- Verification & Compliance: Automated data logging provides proof of cleaning, essential for food safety audits (HACCP, GMP).

For our machines, especially those handling dairy like yogurt or milk which are prone to bacterial growth and buildup (like milkstone), integrating a reliable CIP system is crucial for our clients in developing markets to produce safe, high-quality products consistently.

Conclusion

In short, CIP is a vital automated cleaning process. It uses a sequence of rinses and washes to sanitize equipment like cup fillers without disassembly, ensuring food safety and operational efficiency.

-

Understanding the Caustic Wash process is essential for effective cleaning in food production. Explore this link for detailed insights. ↩

-

The Acid Wash step is crucial for removing mineral scale and residues. Discover more about its importance in cleaning systems. ↩

-

The Final Rinse ensures all cleaning agents are removed, preventing contamination. Learn more about its significance in the cleaning process. ↩

-

Exploring the heating system’s function can enhance your knowledge of effective cleaning solution temperatures and their impact on cleaning efficiency. ↩

-

Learning about instrumentation helps ensure that cleaning parameters are accurately monitored, leading to better cleaning outcomes. ↩

-

Understanding the role of a PLC in CIP systems is crucial for optimizing cleaning processes and ensuring efficiency. ↩