What is the Difference Between Automatic and Semi-Automatic Cup Filling and Sealing Machines?

Having trouble deciding between automatic and semi-automatic machines? It can be a big investment, so you want to get it right.

The main difference is labor. Automatic machines need someone to make sure they keep running. Semi-automatic machines need workers to help with the operation.

Choosing the right machine can be tricky. It’s all about finding the best fit for your business and what you’re trying to achieve.

What is an Automatic Cup Filling Machine?

Are you thinking about speeding up your cup filling? An automatic machine could be just what you need.

Automatic cup filling machines handle the entire filling process. They do it without needing constant human help. They fill containers with liquids, pastes, or granules.

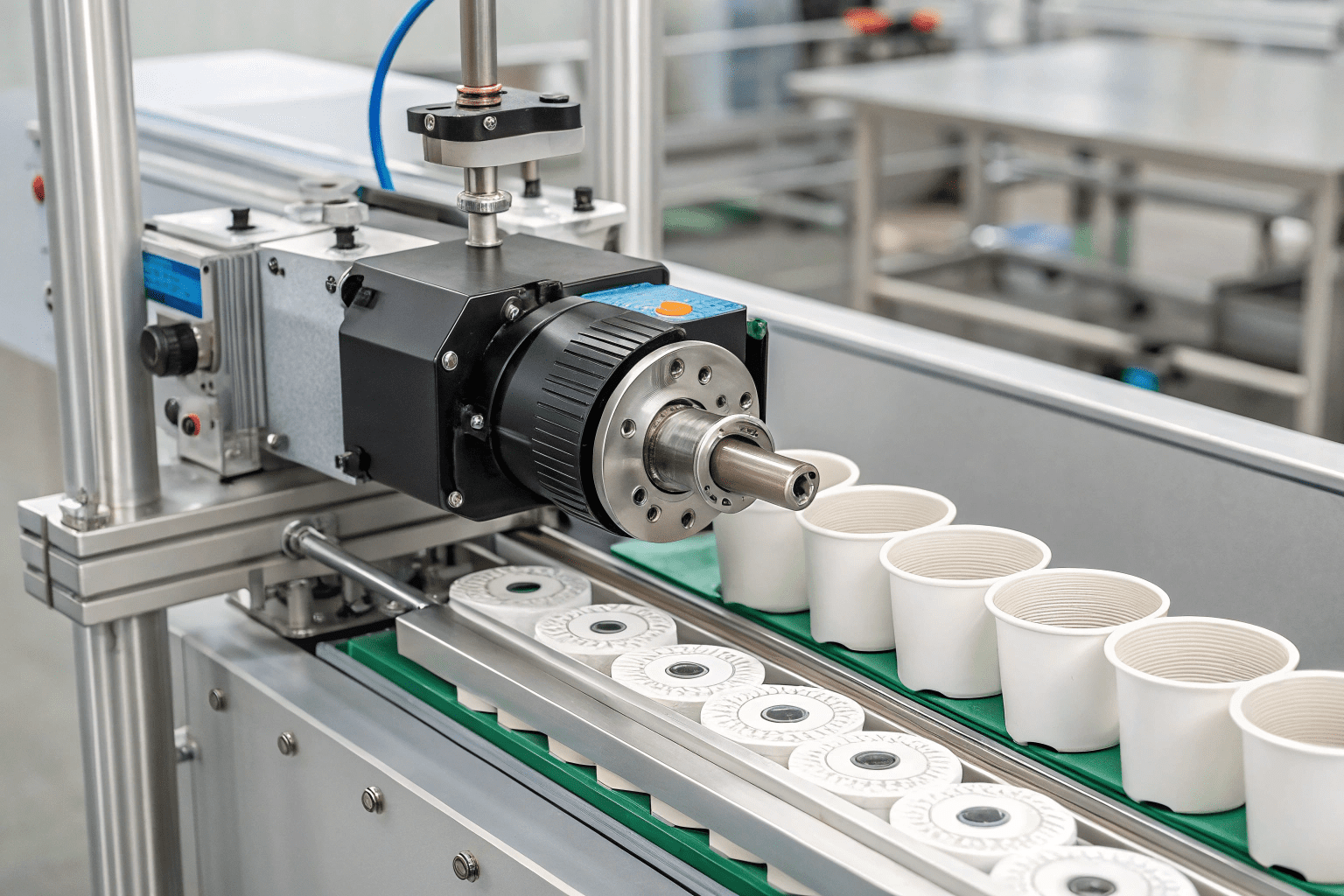

Dive deeper, an automatic cup filling machine is a big step up in production. These machines are designed to take care of everything. Think of a production line where cups or containers move along a conveyor belt. The machine fills each one with the exact amount of product. This could be anything from yogurt to juice. It’s all done automatically, very fast, and very precise.

| Feature | Description |

|---|---|

| Operation | Fully automated; requires minimal human intervention. |

| Speed | High-speed filling; capable of handling large volumes quickly. |

| Precision | Highly accurate filling; ensures consistent product quantity in each container. |

| Versatility | Can be adapted to fill various products, including liquids, pastes, and granules. |

| Maintenance | Requires regular maintenance, which can be complex due to the automated systems, but it is predictable and can be scheduled to minimize production downtime. |

It’s not just about speed, though. These machines are also about accuracy. They make sure every container has the same amount of product. This consistency is hard to achieve with manual filling. Automatic machines also reduce waste.

What is an Automatic Cup Sealing Machine?

Wondering how to keep your products fresh and secure? An automatic sealing machine might be your answer.

Automatic cup sealing machines seal the tops of containers. It is all done automatically, protecting the contents inside.

Let’s dive deeper. These machines are built to seal containers quickly and reliably. Imagine a line of filled cups moving down a track. The machine places a seal on each one, pressing it down firmly. This seal can be made of foil, plastic, or another material. The machine does this without any help, making sure each cup is airtight.

| Feature | Description |

|---|---|

| Operation | Fully automated; seals containers without human intervention. |

| Speed | High-speed sealing; matches the pace of filling machines in a production line. |

| Precision | Ensures a consistent, tight seal on every container. |

| Versatility | Can be adjusted to seal various types of containers and sealing materials. |

| Maintenance | The maintenance is complex due to the automated systems, but it is predictable and can be scheduled. |

The real benefit is in the protection. A good seal keeps the product fresh longer. It also prevents spills and contamination. This is crucial for maintaining quality, especially with food and drinks. An automatic sealing machine makes this process fast and efficient.

What is a Semi-Automatic Cup Filling and Sealing Machine?

Need a balance between automation and manual control? A semi-automatic machine might be the perfect fit.

Semi-automatic machines need some help from workers. They don’t do everything by themselves, but they still speed things up.

Let’s explore this further. Semi-automatic cup filling and sealing machines combine automation with manual steps. For instance, a worker might place cups into a mold by hand. This is often necessary for cups with unusual shapes. Ones that a machine can’t easily drop into place. Once the cups are set, the machine might fill them automatically. Then, a worker might need to place the seals on top before the machine presses them down.

| Feature | Description |

|---|---|

| Operation | Requires manual assistance1 for some steps, like loading cups or placing seals. |

| Speed | Moderate speed; faster than fully manual methods, but slower than fully automatic systems. |

| Precision | Offers good control over filling and sealing, but relies on operator accuracy2 for some steps. |

| Versatility | Can handle a variety of cup shapes and sizes, especially those that are difficult for fully automatic machines. |

| Maintenance | Simpler and less frequent, due to their less complex design, which can be a significant advantage for smaller operations. |

The degree of automation can vary. It depends on the specific machine and the product. The key is that semi-automatic machines require human input at certain points. This makes them more flexible.

Conclusion

Automatic machines handle everything, needing only supervision. Semi-automatic machines require workers to participate in the process.