Are you concerned about the longevity of your investment in packaging equipment? It is understandable if the machine gets damaged.

With proper use and maintenance, a cup filling and sealing machine can typically last for 5-10 years, or even longer. Factors like operating environment and usage patterns play a big role.

It’s a significant investment. Here’s a breakdown of what affects lifespan and how to maximize it. I will also touch on the maintenance procedures.

What is the Lifespan of a Sealing Machine?

Wondering how long your sealing machine will keep your products fresh and secure? It depends.

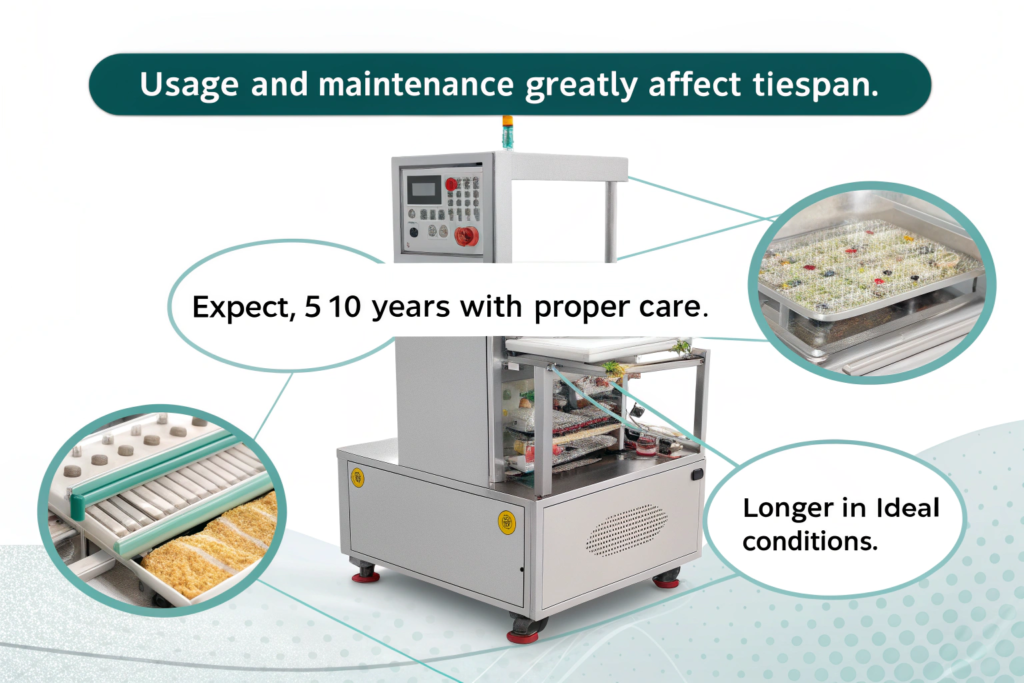

The lifespan of a sealing machine, like its filling counterpart, is heavily influenced by usage and maintenance. Expect a similar 5-10 year range with proper care, possibly longer in ideal conditions.

The main different components affect lifespan, so understanding them is key. I will explain it below.

Factors Affecting Lifespan:

The life of your machine is not fixed. So how long it lasts depends on several factors:

-

Usage Patterns:

- Intermittent Use: Machines used periodically, with breaks between production runs, will generally last longer.

- Continuous Operation: Running a machine at high speed, 24/7, without breaks, will accelerate wear and tear.

-

Operating Environment:

- Ideal Conditions: A clean, dry, temperature-controlled environment is best.

- Harsh Conditions: Dust, humidity, extreme temperatures, and corrosive substances (acids or alkalis) can significantly shorten a machine’s lifespan.

-

Maintenance

- Regular cleaning

- Checking

| Factor | Impact on Lifespan | Recommendation |

|---|---|---|

| Usage (Intermittent) | Longer lifespan due to reduced wear and tear. | Ideal for maximizing machine life. |

| Usage (Continuous) | Shorter lifespan due to increased stress and potential for overheating. | Schedule regular maintenance breaks; consider a more robust machine designed for continuous use. |

| Environment (Ideal) | Prolongs lifespan by minimizing corrosion and component degradation. | Maintain a clean, dry, and temperature-controlled workspace. |

| Environment (Harsh) | Significantly reduces lifespan due to accelerated corrosion and component failure. | Consider specialized machines designed for harsh environments; implement rigorous cleaning. |

| Maintenance(Regular) | Prolongs lifespan. | Clean after use. |

| Maintenance(Irregular) | Shorten Lifespan | Must maintain timely. |

How Do You Maintain a Sealing Machine?

Worried about machine breakdowns and costly repairs? I too was.

Maintaining a sealing machine is primarily about regular, thorough cleaning. Focus on areas that contact the product, and lubricate moving parts. Replace consumable parts like O-rings periodically.

Dive deeper to maintain the machine and the cleaning. Let’s get it.

Maintenance Steps.

-

Cleaning is Key:

- After Every Production Cycle: Clean the pump and any parts that come into contact with the filling material. This prevents residue buildup, corrosion, and sticking.

- Thorough Cleaning: Use appropriate cleaning agents (check the machine’s manual) and ensure all residue is removed.

-

Lubrication:

- Moving Parts: Regularly oil or grease lifting mechanisms, bearing shafts, and adjustment modules. This reduces friction and wear. Refer to your machine’s manual for specific lubrication points and recommended lubricants.

-

Consumable Parts Replacement:

- O-rings and Spacers: These parts, especially on the pump, are subject to wear and tear. Expect to replace them every 6-12 months, depending on usage.

- Other Consumables: Check your machine’s manual for other parts that may require periodic replacement (e.g., sealing jaws, heating elements).

-

Professional Support:

- Electronic Issues: For problems with the machine’s electronic components, contact customer service.

- Complex Repairs: If you encounter issues beyond basic maintenance, on-site engineer support may be available.

| Maintenance Task | Frequency | Purpose |

|---|---|---|

| Cleaning (Pump & Contact Parts) | After each production cycle. | Prevent residue buildup, corrosion, and sticking. |

| Lubrication (Moving Parts) | Regularly (refer to manual for specific intervals). | Reduce friction and wear on moving parts. |

| O-ring/Spacer Replacement | Every 6-12 months, or as needed based on usage. | Ensure proper sealing and prevent leaks. |

| Other Consumable Parts | As indicated in the machine’s manual. | Maintain optimal machine performance and prevent breakdowns. |

| Professional Support | When encountering electronic issues or complex problems beyond your ability. | Get expert assistance to resolve issues and prevent further damage. |

Conclusion

A cup filling and sealing machine’s lifespan, often 5-10 years or more, hinges on proper usage, a suitable environment, and consistent cleaning. Regular maintenance, especially cleaning and part replacement, is key.

| Maintenance Task | Frequency | Purpose |

|---|---|---|

| Cleaning (Pump & Contact Parts) | After each production cycle. | Prevent residue buildup, corrosion, and sticking. |

| Lubrication (Moving Parts)1 | Regularly (refer to manual for specific intervals). | Reduce friction and wear on moving parts. |

| O-ring/Spacer Replacement2 | Every 6-12 months, or as needed based on usage. | Ensure proper sealing and prevent leaks. |

| Other Consumable Parts | As indicated in the machine’s manual. | Maintain optimal machine performance and prevent breakdowns. |

| Professional Support3 | When encountering electronic issues or complex problems beyond your ability. | Get expert assistance to resolve issues and prevent further damage. |

-

Explore this resource to learn effective lubrication techniques that can enhance machinery performance and longevity. ↩

-

This link will provide insights on O-ring and spacer maintenance, ensuring your machinery operates without leaks. ↩

-

Discover when to call in the experts to avoid costly repairs and ensure your machinery runs smoothly. ↩