What is an Ice Lolly Filling and Sealing Machine?

Starting an ice lolly business seems simple, but manual filling is slow, messy, and inconsistent. This inefficiency eats into your profits and limits how much you can possibly produce.

An ice lolly filling and sealing machine is an automated system that handles the entire production process. It loads empty soft tubes, fills them with liquid like juice, and then heat-seals them shut. This creates the classic ice pop ready for freezing, all done quickly by one machine.

This process might sound straightforward, but the technology behind it is what truly transforms a small-scale operation into a mass-production powerhouse. Let’s break down how this machine actually works. Understanding each step will show you why it’s a game-changer for so many of my clients and why it could be for you, too.

How Does the Machine Handle the Filling and Sealing Process Step-by-Step?

You know the machine works, but the internal process can seem like a black box. Without understanding the steps, you can’t really be sure it is reliable or efficient.

The process is a precise, automated sequence. It starts by loading empty tubes onto a conveyor chain. Then, it uses vacuum filling for bubble-free accuracy, heats the tube’s opening, and finally clamps it tight to create a perfect, leak-proof seal for every single lolly.

Let’s dive deeper into this workflow. The entire operation is designed for speed and precision, moving from one station to the next without any manual help. I remember when we first designed this system for a client in Southeast Asia. They were struggling with inconsistent fill levels and messy sealing by hand, which meant a lot of wasted product. Automating the process with one of our machines eliminated these problems overnight. The machine’s chain-driven system ensures every bottle moves at the exact same pace, which is crucial for the timing of the next steps. The vacuum filling, in particular, was a huge relief for them. It not only ensures an accurate fill but also prevents the sticky messes that used to slow down their entire packaging line.

Key Stages Explained

Here is a simple breakdown of the critical stages.

| Stage | Description | Why It’s Important |

|---|---|---|

| 1. Auto Tube Loading | The machine automatically picks and places the soft plastic tubes onto the conveyor chain. | It eliminates slow manual labor and ensures consistent placement for perfect filling. |

| 2. Vacuum Filling1 | A nozzle descends, creates a vacuum to remove air, and then fills the tube with liquid. | This prevents air bubbles, stops messy overflows, and guarantees each lolly has the same amount of product. |

| 3. Heat Softening | A heating element gently warms the open end of the plastic tube until it’s pliable. | This prepares the plastic for a strong, clean seal without burning or damaging the tube material. |

| 4. Clamping & Sealing2 | A mechanical clamp presses the softened plastic together, fusing it shut to form the final shape. | This creates the final, durable seal that keeps the product fresh and prevents any leaks during freezing or transport. |

Why is Customization So Important for Your Ice Lolly Machine?

You might find a standard machine, but your ice lolly tubes are a unique shape or size. A one-size-fits-all machine will cause jams, waste product, and create production nightmares.

Customization is not just a feature; it’s essential because every product is different. The machine must be tailored to your specific tube dimensions, the type of liquid you’re filling, and your desired production speed. This guarantees smooth operation and maximizes your efficiency from day one.

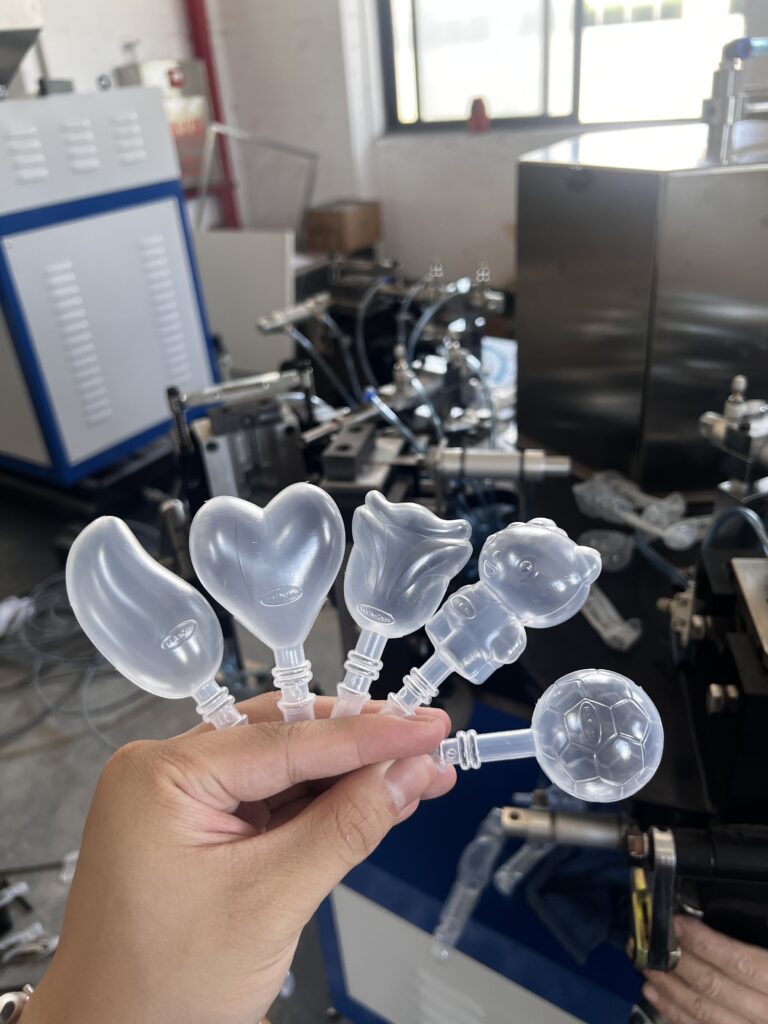

Think of it like buying a suit. An off-the-rack suit might fit okay, but a tailored one is perfect. It’s the same with these machines. We always ask our clients to send us samples of their empty tubes and the product they want to fill. I once worked with a client from Africa who sent us a very unique, star-shaped ice lolly tube made from a thicker-than-usual plastic. A standard machine’s heating element and clamp would have either failed to seal it or crushed it completely. We had to design a custom mold, a stronger clamping system, and adjust the heating temperature just for them. This attention to detail is what separates a successful, profitable production line from a frustrating, money-losing one.

Key Customization Areas

Here are the main things we adjust for each client to ensure their machine works perfectly for their product.

| Customization Area | What We Adjust | Why It Matters for You |

|---|---|---|

| Tube Dimensions | The molds, grippers, and conveyor chain are all built to match your tube’s height, width, and shape. | This prevents tubes from falling over, jamming in the line, or being sealed incorrectly. It ensures a smooth, continuous flow. |

| Filling Material | We adjust the pump system and nozzle design for thin liquids, thick pastes, or even products with small fruit bits. | This guarantees accurate filling without causing clogs or damaging the texture of your product. Your quality stays high. |

| Production Capacity | We can build machines with more or fewer filling nozzles to match your target output per hour. | You get a machine that matches your business size and growth plans, whether you need 2,000 or 70,000 pieces per hour. |

What Business Opportunities Can This Machine Unlock for You?

You have a great ice lolly recipe but can’t produce enough to meet potential demand. This situation keeps your business small and prevents you from entering larger, more profitable markets.

This machine is the key to scaling up production. It allows you to chase bigger contracts with supermarkets and distributors, giving you the confidence that you can meet their demand.

This single piece of equipment opens doors to mass production. You can finally move from being a small local shop to a regional supplier. Many of our clients in developing countries start exactly this way. They see a popular snack, like these ice lollies, in a supermarket and think, "I can make that better or cheaper." But they can’t do it by hand. I had a client in South America who started this way. He was making a few hundred a day for his local neighborhood, and his product was a huge hit. After getting one of our machines that could produce 5,000 an hour, his business exploded. Within a year, his brand was in major retail chains across his entire country. The machine is the bridge between a small idea and a large-scale business. It gives you the power to compete with the big guys.

Markets You Can Target

With high-volume production, you can explore new and much larger sales channels that were impossible before.

| Market Channel | Why It Becomes Possible | Potential Outcome |

|---|---|---|

| Supermarket Chains3 | You can consistently meet their high-volume orders and strict quality standards for packaging and fill weight. | You gain access to a massive customer base, leading to consistent, large-scale revenue and brand visibility. |

| Regional Distributors | Your increased capacity allows you to supply wholesalers who cover a much larger territory than you can alone. | This expands your geographic reach far beyond your local area without needing your own logistics network. |

| School & Event Catering | You can produce thousands of units quickly for special events, school lunch programs, or festivals at a competitive price. | This opens up completely new and profitable B2B revenue streams that have high, predictable demand. |

| Exporting4 | A reliable, automated process ensures your product meets international quality standards for hygiene and packaging. | This allows you to access new markets in neighboring countries, dramatically increasing your potential customer base. |

Conclusion

In short, an ice lolly machine automates your production from filling to sealing. Customizing it for your product unlocks mass production, letting you scale your business and enter larger markets.

-

Understanding Vacuum Filling can enhance your knowledge of efficient production methods and quality control. ↩

-

Exploring Clamping & Sealing techniques can provide insights into effective packaging solutions and product preservation. ↩

-

Explore how partnering with Supermarket Chains can significantly boost your sales and brand visibility. ↩

-

Learn how Exporting can open new markets and expand your customer base internationally. ↩